INPRO Assessment of the Planned Nuclear Energy System of Belarus

Contents

- 1 Introduction

- 2 ECONOMICS

- 3 INFRASTRUCTURE

- 3.1 INTRODUCTION

- 3.2 USER REQUIREMENT UR1 — LEGAL AND INSTITUTIONAL INFRASTRUCTURE

- 3.3 USER REQUIREMENT UR2 — INDUSTRIAL AND ECONOMIC INFRASTRUCTURE

- 3.4 USER REQUIREMENT UR3 — POLITICAL SUPPORT AND PUBLIC ACCEPTANCE OF NUCLEAR POWER

- 3.4.1 Criterion CR3.1 — information

- 3.4.1.1 EP3.1.1 — national energy policy

- 3.4.1.2 EP3.1.2 — informing the public about benefits of nuclear energy

- 3.4.1.3 EP3.1.3 — information on operation of nuclear facilities

- 3.4.1.4 EP3.1.4 — addressing public concerns regarding nuclear installations

- 3.4.1.5 EP3.1.5 — use of communication experts for public information

- 3.4.2 Criterion CR3.2 — participation of public

- 3.4.3 Criterion CR3.4 — political environment

- 3.4.4 Final assessment of user requirement UR3 — political support and public acceptance

- 3.4.1 Criterion CR3.1 — information

- 3.5 USER REQUIREMENT UR4 — HUMAN RESOURCES

- 3.5.1 EP4.1.1 — educational and training system in nuclear power projects

- 3.5.2 EP4.1.2 — attractiveness of nuclear power sector

- 3.5.3 EP4.1.3 — capacity to accept additional load of nuclear power programme

- 3.5.4 Criterion CR4.2 — safety and security culture

- 3.5.5 Final assessment of user requirement UR4 — human resources

- 3.6 SUMMARY AND CONCLUSIONS OF ASSESSMENT OF BELARUS’ INFRASTRUCTURE

- 4 WASTE MANAGEMENT

- 5 References

Introduction

General information on Belarus

Belarus is located in the eastern part of Europe. In the west it borders Poland, in the northwest Lithuania, in the north Latvia, in the north-east and east Russia, in the South Ukraine. The territory of Belarus is crossed by several European transport corridors providing the shortest communication routes from the central and eastern regions of the Russian Federation to western European countries, and between the Baltic and the Black seas.

The territory of Belarus is 207 600 square kilometers. The longest distance, 650 km, is from

west to east, and 560 km from north to south. By the size of its territory, Belarus occupies the

thirteenth place among the European countries and the sixth among the Commonwealth of

Independent States (CIS) countries (following Russia, Kazakhstan, Ukraine, Uzbekistan and

Turkmenistan).

The topography of Belarus features predominantly low hilly land with an average altitude of

160 m above sea level, while the highest point is only 345 m above sea level. The flatland

nature of its surface creates favourable conditions for the expansion of human settlements,

agricultural development of the territory, construction of industries, transport and service

lines, and development of tourism and recreational services.

Agricultural land occupies 45% of the territory, including 30% of tillage. There are 0.9

hectares of cultivated land, including 0.6 hectares of tillage, per capita in Belarus.

Forests account for 36% of the country's territory. There are 0.7 hectares of woods and 111 m3 of timber per capita here, which is almost twice as high as the average European level. The trees growing in Belarus mostly belong to valuable species. Pine occupies 52.9%, fir 10.5%, oak and other hard-leaved species 3.8%, birch 18.1%, aspen 2.3%, alder 9.6% of the forest covered area. However, the species composition of the woods is far from optimal. Considering the fertility of the forest soils, the area under hard-leaved species could be expanded two-fold. The forest potential in Belarus is rather high; the annual increment of timber reserves is 25 million cubic meters, while the actual timber production is 10–11 million cubic meters per year. The area with mature woods is steadily growing. The forest, apart from being a source of timber, performs numerous ecological functions (such as water protection, water regulation, soil protection, assimilation functions), and also sanitation,

recreation and health-building functions. Belarusian forests play an important biospheric role

and make a considerable contribution to the ecological stabilization of central and eastern

Europe.

Natural resources

About 30 kinds of mineral raw material can be found in Belarus (more than 4000 deposits and fields). The most significant are potassium salts; their reserves occupy one of the leading places in Europe. The reserves of rock-salt are also notable. The prospected industrial reserves of these minerals in the Mozyr, Davydov and Starobin deposits exceed 22 billion tons.

The country is rich in rock products, such as granites, dolomites and dolomite limestone, marl, chalk, fusible and refractory clay, loam, sand and gravel. There is raw material for the production of natural paints (e.g. marsh iron ore, ochre, glauconite).

The availability of high quality water resources stimulates the construction of sanatorium and resort complexes and the development of companies trading and exporting mineral curative and table water. In recent years, more than 63 springs have been discovered with a potential supply of 155 572 m3 per day.

Belarus possesses sufficiently strong raw material reserves for the production of construction material. However, there is a deficit of high-grade glass-making sand and clay.

Peat fields are widely spread in Belarus, although — due to intensive exploitation — the peat fields as production sources have largely been exhausted. The total geological reserves are estimated at 4.4 billion tons. Sapropels are an important natural raw fertilizer; their estimated reserves are three billion cubic meters. A comprehensive utilization of peat and sapropel resources is important.

The reserves of oil are not large and oil is extracted in small quantities. Deposits of brown coal have been found in Belarus. However, its low caloric value and high ash content preclude its utilization in energy production in the near future. Briquetted brown coal (possibly, with peat) can be used only as household fuel or as raw material for producing wax and plant growth stimulants.

The Belarusian territory is promising in terms of ferrous and non-ferrous metal. Geological exploration in search for amber, titanium and rare-earth metal deposits is under way.

The existing mineral resources fully provide for the future needs of potassium and rock salt, lime and cement, refractory and ceramic clays, construction sand, gravel and facing stone.

It must be noted that the mining resources in Belarus are still insufficiently investigated. The new economic situation and the emergence of sophisticated technologies call for a revaluation of the deposits and reserves of mineral resources in the Republic, and a more efficient utilization of all components of the resources mined.

Climate

The climate of Belarus is moderately continental with mild and humid winter, warm summer and wet autumn. The mean temperature in January is from – 4 °C in the south-west to – 8 °C in the north-east of the country; that of July is + 17 to + 19 °C. The annual precipitation is 550–650 mm in lowland areas and 650–750 mm in flatland and elevated areas. The average vegetation period is 184–208 days. The climatic conditions in Belarus are favourable for growing staple grain crops, vegetables, fruit trees and bushes which are common for moderate climate zones of east Europe, especially for cultivating potatoes, flax, annual grass and fodder root crops.

There are more than 20 000 rivers and streams in Belarus with the total length of 91 000 km, and about 11 000 lakes, including 470 lakes with the area exceeding 0.5 km2 each. Naroch is the largest lake in Belarus (79.2 km2, the deepest point about 25 m). More than half of the water resources belong to the Black Sea basin, the rest belongs to the Baltic Sea basin. The Pripyat, Dnieper, Nieman, Berezina and Zapadnaya Dvina rivers, and also the Dnieper-Bug canal are important for river navigation.

More than 145 artificial lakes have been created in Belarus. The most important is the Viliya Reservoir (75 km2 ) that gives birth to the Viliya–Minsk system of canals along which water from the Viliya river is directed to Minsk, the Republic's capital.

The renewable resources of surface and underground fresh water in the country are sufficient for meeting the present and future needs: the river water resources constitute 57.9 km3/a. The total volume of water accumulated in lakes is estimated at 6–7 km3, the volume of artificial reservoirs is 3.1 km3. The average water intake for the household and industrial purposes does not exceed 5–7% of annually renewable water reserves.

Territorial division

Belarus consists of six oblasts which include 118 administrative districts and the city of Minsk. There are 104 towns and 108 settlements with the status of a town.

Regional differentiation is not high in Belarus, although the oblasts differ in their level of socioeconomic development and the structure of their economy. The main socioeconomic, natural geography and ecological features include:

- A higher level of industrial development in the eastern regions and, therefore, a high level of production and consumption of energy and material;

- The presence of major chemical and petrochemical complexes in Vitebsk, Grodno, Gomel, Minsk and Mogilev oblasts, which are a severe burden on the environment;

- A high concentration of industrial production in the capital and major cities;

- Differences between oblasts in the level of agricultural production connected with soil, climatic, ecological and other local characteristic features, and with differences in the location of main branches of agricultural specialization;

- Main concentration of social infrastructure complexes in Minsk, oblast centres and other towns. The city of Minsk is situated in the central part of Belarus and is the national capital and the centre of the oblast and district with the same name. Minsk is granted a special status. It is the largest political, economic, scientific and cultural centre of the Republic. The population is 1 885 100. The territory is 255.8 km2. Administratively, it is divided into nine districts and has one city council with jurisdiction over some villages and urbanized settlement. With about 300 industrial enterprises, Minsk has the largest industrial production in Belarus — more than 22% of the country’s industrial output. The city of Minsk exceeds the other regions in the output of machine engineering, electric energy, non-ferrous metallurgy, medical and printing industries. The prevalence of machine engineering industries — producing more than half the city’s industrial products — is a characteristic feature of the capital. There are such major enterprises as BelavtoMAZ, Minsk Tractor Works, Minsk Engine Works, and Atlant. Electric energy, and the food industry also has a high share. The industrial complex of the city possesses a high export potential: at a number of companies up to 80% of output is exported.

Population

The size of the resident population of Belarus amounted to 9 465 200 people as of the beginning of 2012. Over 24% of the urban population resides in the Belarusian capital.

Belarus is a comparatively densely populated country. Average population density is 46 persons per sq km. The territory of Belarus is inhabited rather uniformly, most densely in central regions.

The sex/age structure of the population is as follows: males account for 45.7% and females for 54.3%. Dynamics of size of population in Belarus during 1990–2011 are given in Table 1.

| 1990 | 2000 | 2005 | 2006 | 2007 | 2008 | 2009 | 2010 | 2011 | |

| Number of resident population, thousands. | 10190 | 9990 | 9800 | 9751 | 9714 | 9690 | 9514 | 9500 | 9481 |

Belarus is a polyethnic and polyconfessional State in which over 130 nationalities (comprising just under 20% of the total population) reside with Belarusians (81.2%).

State institution

The President of Belarus is the head of State, guarantor of the Constitution and civil rights. The President takes measures to maintain the sovereignty of the Republic, its national security and territorial integrity, and provides political and economic stability, succession and cooperation of State bodies, and is a mediator between them.

In accordance with the Constitution, the President issues edicts and decrees that have binding force on the whole territory of Belarus. In cases stipulated by the Constitution, the President issues decrees with the force of law. Directly or through special bodies he provides for the execution of decrees and edicts.

The Parliament, i.e. the National Assembly, is the representative and legislative body of the Republic. The Parliament consists of two chambers, the Chamber of Representatives and the Council of the Republic. The Constitution defines the composition and the procedure of forming the chambers. The Chamber of Representatives consists of 110 deputies elected on the basis of universal, free, equal and direct suffrage, by secret ballot. The Council of the Republic is the chamber of territorial representation. In each region and in the city of Minsk, eight members of the Council of the Republic are elected at sittings of deputies by secret ballot. A further eight members are appointed by the President. Each Chamber elects its own Chairman and vice-chairmen who run the sittings and manage the internal regulations.

In conformance with the Constitution, the Chamber of Representatives is entitled to hear the reports of the Prime Minister on the Government's programmes of activities, give a vote of no confidence to the Government, and consider the issue of confidence to the Government upon the request of the Prime Minister. The Chamber of Representatives appoints elections of the President and accepts the dismissal of the President.

The Council of the Republic may cancel the decisions of local councils of deputies which run contrary to the national legislation, and takes decisions on dissolution of a local council in cases of systematic or gross violations of the legislation and in other cases stipulated by the law.

The Constitution establishes the right of the Council of the Republic to consider the decrees of the President on introducing the State of emergency, martial law, total or partial mobilization, and must take an appropriate decision within three days after their submission.

The Parliament takes a decision on the President's dismissal.

The term of office of the Parliament is four years and may be extended only in event of war. Local government and self-government is exercised through local councils of deputies, executive and management bodies, bodies of territorial public self-management, local referenda and meetings.

The local councils of deputies are representative bodies of State power in the respective territorial administrative units and the main bodies of self-management.

The Constitution establishes the exclusive competence of local councils of deputies for approval of programmes of economic and social development, local budgets and report on their execution, imposition of local taxes and duties in conformance with the law, determination, in conformance with the law, of the procedure of managing communal property, and the conduct of local referenda.

The local councils of deputies are elected by citizens of the respective territorial administrative units for four years.

In conformance with the Fundamental Law, heads of the local executive and management bodies are appointed and dismissed by the President or in the order established by him, and approved by the respective local councils of deputies.

The Constitution of Belarus establishes a binding force of the decisions of local councils of deputies, and of executive and management bodies on their respective territory, taken within their frame of competence, which is one of the guarantees of their efficient work.

Economy

The Belarusian economy has experienced steady and sizable growth since 1996. Following an estimated decline of close to 40% during 1992–95, gross domestic product (GDP) growth resumed in 1996. During 1996–2004, the GDP grew by 77.4%, at 6.6% on average per annum. Rates of GDP growth in 2005–2010 fluctuated between 7.0% and 10.2% (except in 2009, Table 2) according to the data of the National Statistics Committee of Belarus[1][2].

| 1995 | 2000 | 2005 | 2006 | 2007 | 2008 | 2009 | 2010 | |

| GDP, bln. BRB | 121403 | 9134 | 65067 | 79267 | 97165 | 129791 | 137442 | 162964 |

| GDP, % in relation to previous year, const. prices | 89.6 | 105.8 | 109.4 | 110.0 | 107.0 | 110.2 | 100.2 | 107.6 |

| GDP structure,%: | ||||||||

| Industry | 27.6 | 28.4 | 27.6 | 26.8 | ||||

| Agriculture | 15.1 | 7.9 | 7.5 | 7.5 | ||||

| 7.5 Construction | 5.4 | 6.9 | 7.9 | 11 | ||||

| Transport & communication | 12.2 | 9.5 | 9.2 | 9.5 | ||||

| Trade & catering | 7.6 | 9.4 | 10.3 | 11.1 | ||||

| Net Taxes | 9.7 | 14 | 14.2 | 12.8 | ||||

| Other | 22.4 | 23.9 | 23.3 | 21.3 |

Economic growth in Belarus has been rather broad-based. It has been driven primarily by improvements in labour productivity and increases in both energy efficiency and capacity utilization. Fiscal and external adjustments have been significant and have helped to improve the macroeconomic conditions for growth. In contrast to some other CIS countries, where growth and exports remain concentrated in the extracting sectors with limited employment opportunities, the growth structure in Belarus has been much more beneficial for labour. Growth in labour-intensive sectors, backed by Government wage and income policies, has helped to ensure that the benefits from recent growth have been fairly broadly shared by the population. Poverty rates have declined substantially, while inequality has remained stable and moderate. The poverty headcount ratio (national definition) fell from 38.6% of the population in 1996 and 46.7% in 1999 to 17.8% in 2004, while inequality, which was moderate by regional standards during the entire period of economic growth, decreased further after 2001. This decline in poverty is, however, in line with a broader trend in poverty reduction that took place recently in the transition economies. This remarkable achievement is the result of a unique constellation of factors — rapid ‘catch-up’ growth in CIS accompanied by reductions in inequality in some countries.

Before 2001, in terms of economic growth, Belarus outperformed both the central eastern European and Baltic States (CEEBS) and the CIS but during the second period (2001–04), the CIS as a group had a stronger performance than Belarus and the difference in growth rates between Belarus and the CEEBS decreased. In addition, Belarus' relatively strong debt and trade indicators in the late 1990s should be treated with caution: the use of the official exchange rate at the time of the multiple exchange rate system distorted the data. The application of the alternative exchange rate revealed that during the first period of growth, Belarus had much more serious problems with its balance of payments than is usually recognized. In 1998, the current account deficit amounted to almost 16% of the GDP, while the official figures show only 7%. However, both measures show a strong post-1999 recovery in all main indicators of external vulnerability, indicating a strong external adjustment.

The macroeconomic performance during the years of economic growth has been rather mixed. Belarus has managed to maintain moderate budget deficits and debt levels. However, such indicators as inflation, foreign direct investment inflow and the current account balance were weak. Inflation in Belarus, which is being reduced substantially, remained significantly higher during both periods than in other transition economies, including neighbouring countries. The current account position is still precarious, given the low level of reserves, the inability to attract a sizable amount of direct foreign investment, and the limited access to international financing.

Overall, the Belarusian economy has a number of features that make it quite different from its neighbours in both the CIS and the CEEBS. These features include:

- The dominance of traditional firms (State-owned or partially privatized) in production and exports; *The high degree of Government intervention in state enterprise operations, including the preservation of some elements of central government planning of output, wages, and employment; *The high level of the tax burden and the major budget redistribution of funds aimed at supporting traditional firms and employment;

- Quite substantial dependence on trade with the Russian Federation along with the slow pace of geographic diversification of exports.

The pattern of changes in the structure of the nominal GDP by sector in Belarus is similar to that in other transition economies but the magnitude of these changes is somewhat different. As in other transition economies, especially those considered as over-industrialized, the share of services in GDP structure increased. The reduction in the share of agriculture has also been in line with the developments in other CEEBS. At the same time, the increase in the share of services is relatively moderate. Moreover, in 2000–2006 these trends were reversed — the share of industry actually increased while the share of services declined. However, changes in the nominal GDP structure are not the most informative in the environment of changing relative prices.

Primary energy supplies

In the past several years, Belarus has demonstrated considerable growth in its economy. The GDP of the country more than doubled from 2000 to 2010.

However, domestic fuel use during the same period was very moderate. Belarus remained highly dependent on its single foreign fuel supplier – the Russian Federation.

Belarus remained one of very few countries in the world which notably increased the share of natural gas in the national energy mix in the given period without having its own reserves of this energy resource. For example, the share of natural gas used for electricity generation is one of the highest in the world and equals 95–96%. At the same time, underground storage does not meet modern requirements for energy security (25% of total annual resource consumption).

All these facts jeopardize the efforts of the Belarusian government to sustain successes achieved lately and to create a strong economic basis for further national development.

To address these challenges, reduce energy dependence and lessen the national economy’s vulnerability to energy price shocks in the future a comprehensive energy policy is required.

Primary energy sourse

Imported crude oil and natural gas are the main sources of primary energy for Belarus. The history of these kinds of primary energy is given in Table 3.

| 2000 | 2005 | 2006 | 2007 | 2008 | 2009 | |

| Crude oil, mill. tonnes | 11.9 | 19.2 | 20.9 | 20.0 | 21.5 | 21.5 |

| Natural gas, bill. M3 | 17.1 | 20.1 | 20.8 | 20.6 | 21.1 | 17.6 |

Domestic energy resources

To decrease the share of imported energy sources, it is planned to increase the use of domestic and renewable energy resources. In 2020 domestic resources and renewables will amount to 6.7 million tce.

Biomass

Wood and residues of wood processing are the most important source of domestic fuel in Belarus. At present, biomass reserves in forests of the country are estimated to be 1.43 billion m3. Territory of the country covered by forests is 9.3 million hectares.

Belarus has considerable potential to increase biomass use for energy purposes. It is supposed to increase the use of wood to 11 million m3 (3.1 million tce) per year by 2020.

Peat

Belarus has one of the largest reserves of peat in Europe. More than 9000 deposits of economically justifiable peat extraction have been found there. Their total area is 2.54 million hectares, and peat reserves there are estimated to be 5.65 billion t. Geological reserves of peat in Belarus amount to 4 billion t. Reserves of peat available for energy use are estimated at 100–130 million t.

At present, most of peat produced in Belarus is consumed by housing and utilities as fuel for small boilers, which is the main restriction for its wider use.

Further growth of peat use as a fuel will be possible if new small combined heat and power plants or centralized district heating plants designed especially for its use are built in Belarus.

For this purpose, it is expected to increase peat for energy production by 1.5 million tce by 2020. To achieve this goal, the development of new peat deposits will be necessary with due consideration given to environmental issues.

Lignite

In 2003, the available reserves of lignite in Belarus were estimated to be 151.6 million t. Lignite found in Belarus has the following characteristics:

- Humidity — 56–60%;

- Ash content — 17–23%;

- Sulphur content — 0.6%

- Calorific value — 1500–70 kcal/kg

Dried lignite can be used for briquettes, manufactured jointly with peat as a fuel for hot water boilers. Subject to thermochemical processes, lignite can be used as raw material for liquid fuel or other products.

The largest deposits of lignite in Belarus are located at Zhitkovichi. Its reserves allow to extract annually 2 million t of lignite (0.46 million tce). After completion of feasibility studies, it is planned to develop this deposit and its annual production will reach 0.2 million tce by 2020.

Oil shale

Forecast, reserves of oil shale in Belarus are estimated at 11 billion t. Reserves of the Luban and Turov deposits available for extraction are expected to be around 3 billion t. Oil shale in Belarus is characterized by low calorific value (1000–1510 kcal/kg), and high ash (61–82%) and sulphur content (2.6%) that makes its use for direct combustion impossible. The alternative way to involve oil shale in use in Belarus is to subject it to high-cost thermochemical processes; however, that is not economically feasible at present.

Renewable energy resources

Hydroelectricity

The theoretical potential of hydro resources for electricity generation in Belarus is estimated at 850 MW. However, only 529 MW is technically available. Economically feasible potential for hydroelectricity in Belarus is 250 MW.

Currently (2012), the total installed capacity of hydroelectric power plants is about 32 MW. The strategic goal of Belarus with regard to hydroelectricity is to construct new plants, and reconstruct and recover old hydroelectric power plants (HPPs). According to these plans, total installed capacity of HPPs will reach 120 MW in 2015.

For estimation of the economic feasibility of constructing hydro cascades on such rivers as the Sozh, Pripyat, and Dniepr, more detailed investigation is needed.

In the near future attention should be focused on the use of small hydro units with installed capacity from 50 to 5000 kW each. The use of small hydro generators of capsule design is more advantageous due to lower scheduled outages for maintenance.

Geothermal energy

The most favourable conditions for geothermal potential use in Belarus are in Pripyat and Podlyassk-Belostok cavities where extracted heat resource potential reaches 5–6 tce per m2. To exploit this reserve, a complex of special geological studies is required in order to determine the exact sites for well drilling and development of special technologies for geothermal energy use taking into account high mineralization of this heat source.

Wind energy

According to the meteorological data available, approximately 1840 sites for wind turbine installation are to be found in Belarus. On 1 January 2005, the total installed capacity of wind turbines in Belarus was 0.85 MW, and their annual electricity generation made up 0.4 tce. Currently, in 2012, total installed capacity of wind turbines in Belarus is about 3 MW. The scale of wind electricity is subject to annual correction taking into account possible changes of fossil fuel costs.

Use of wind energy in remote rural areas, farms and greenhouses for electricity generation, heating and water pumping is considered to be the most feasible option for Belarus due to the low average wind speed in the country.

Biogas

Potential for biogas use in Belarus is estimated to be 160 000 tce per year. At present, three pilot biogas projects are completed in Belarus. However, an integrated approach with regard to biogas technologies is needed to make them competitive with traditional ones. Results achieved show that, for biogas projects, it is necessary to take not only costs of electricity and heat generated into account but also environmental effects.

Solar energy

According to meteorological surveys, average solar radiation in Belarus is 243 kcal/m2 day, equal to 2.8 kWh/m2 day. Providing the efficiency of energy transformation is 0.3, the average potential for solar energy production is 0.3 kWh/m2 day.

Possible ways to use solar energy in Belarus are agricultural and domestic applications, mainly for water heating purposes. Potential for use of solar energy in Belarus could amount to 5000 tce.

Solid waste

Total energy reserves possible from solid waste use are estimated to be around 470 000 tce. Providing that the efficiency of the process of transformation of waste into gas equals 30%, total available reserves of this source are 100–120 thousand tce. When considering use of solid waste as an option, it is necessary to take into account its large reserves in all the large cities in Belarus as well as possible environmental effects related to waste use.

Fast growing biomass and agricultural waste

Fast growing biomass of trees and bushes can be used as a fuel or a source of raw material for solid of liquid fuel production. Possible crops of fast growing biomass from one hectare in Belarus may exceed 10 t, i.e. equal to approximately 4 tce per year. If special growing technologies are used, productivity of such plantations can be 2–3 times higher. According to the data of special research, potential of this kind of energy resource in 2020 will reach 350 000 tce.

Agricultural waste also makes up a considerable reserve as energy resource. Total available potential of this alternative fuel in Belarus is estimated at 1.46 million tce per year. Agricultural waste is thought to be widely used as fuel for small heating plants and individual heating systems in rural areas.

By 2020, potential of this energy resource use is estimated at 140–200 thousand tce.

Biodiesel and bioethanol

Belarus has good prospects for the wide use of biodiesel and bioethanol as alternative automobile fuel. Rapeseed, soybean and sugar beet are considered to be the best crops for this liquid fuel production. Biodiesel and bioethanol can be used as additives to traditional fuel or in pure form as main fuel. Total available reserves of these fuel sources are about one million tce, taking into account existing and projected crop productivity and their main use for the food industry.

Should the necessary investment for the industry be available, the volume of biodiesel and bioethanol production could be 110 000 tce in 2020.

For launching bioethanol production in the country, large-scale modernization of existing sugar been processing industry is required. Biodiesel production will be organized at plants for the food industry operating at present.

Secondary energy resources

According to estimates made, the potential volume of secondary fuel energy resources available in Belarus is about 580 000 tce per year, including methane-hydrogen for ethylene production — 162 000 tce, X-oils — 14 500 tce, black liquor — 9200 tce, flax scotch — 36 900 tce, and fuel oil residues — 2400 tce. Efficiency of the secondary energy resources in technology and boilers varies from 70 to almost 100%.

At present, these reserves are partially in use. The most considerable project realized in this field is the utilization of lignin produced at Rechitsa hydrolysis factory for the generation of heat energy.

The use of secondary energy resources at refineries operated in Belarus is expected to increase notably. For example, the volume of oil coke produced at Novopolotsk refinery Naftan as a by-product will be up to 4 000 000 tce in 2015–2020. This energy resource can be used as fuel for heat and electricity generation and may be consumed by either Naftan or power plants and also the construction material manufacturing industry. It is expected to use appropriate technology at Naftan and Novopolotsk CHP.

Belarus also has great potential for use of waste heat resources. Their use in 2006 reached 4.9 million Gcal and the volume of their utilization in 2010 was about 5.9 million Gcal.

Enterprises of chemical and petrochemical industry have the largest reserves for waste heat use (about 96.5% of total reserves available).

Capital investments needed for that purpose will be about 70–80 million USD by 2015. Providing necessary investment is forthcoming, the volume of high-temperature waste heat use will increase by 200 000 tce and of medium- and low-temperature waste-heat by 60 000 tce.

The largest reserves for use of this energy resource are concentrated at the following factories:

- JSC Grodno Azot — production of ammonia fertilizers;

- JSC Gomel Chemical Plant — production of sulphuric acid;

- Naftan refinery — oil processing, including waste heat of hydrogen production;

- Mozyr refinery

The targeted volumes of waste heat utilization can be achieved only if scheduled volumes of oil processing and mineral fertilizer production are guaranteed.

The use of waste heat by factories owned by the Ministry of Industry of Belarus was about 5 925 000 tce in 2010.

Diversification of primary energy supplies to Belarus

At present, Belarus receives all oil and natural gas consumed from a single supplier — the Russian Federation. Such a structure of routes of primary energy transportation makes the economy of Belarus highly vulnerable to energy price changes and supply interruptions in case of damage to oil and gas transportation pipelines or political conflicts, for example.

However, the number of possible economically feasible alternatives of primary energy resource supplies to the country is very limited.

Taking into account the locations of existing and prospective gas and oil fields in the world and also the political relations between Belarus and other countries, it is worth examining the effectiveness of organization of energy resource supplies from Azerbaijan, Venezuela, Iran, and Kazakhstan.

Preliminary feasibility studies of energy supplies from these countries have already been conducted and detailed examination of economic effectiveness of these projects is necessary to make the final decision. The most important alternative routes of primary energy supply to Belarus are for:

- Natural gas — Kazakhstan, Turkmenistan and Uzbekistan;

- Oil — Azerbaijan, Kazakhstan, Iran, Iraq and Venezuela;

- Coal — Kazakhstan, Poland and Ukraine.

Energy sector

General data

The total installed capacity of all power plants in Belarus in 2010 was about 9.1 GW, of which 8266.5 MW of thermal capacity plants belong to the national utility Belenergo. The total length of the electricity grid was 238 800 km, and the total length of heat transmission pipelines was 5.100 km.

In 2010, the overall consumption of electricity in Belarus was 37.46 billion kWh. Electricity generation by the national power plants amounted to 34.5 billion kWh, of which 32.5 billion kWh were generated by Belenergo power plants. Electricity import in 2010 was 2.97 billion kWh. .

Heat generation by power plants and district heating plants belonging to Belenergo in 2010 totalled 36.72 million Gcal. Electricity in transmission and distribution grid and heat energy losses made up about 11% and 10%, respectively. .

Total fuel consumption of Belenergo generation facilities in 2006 was 1 3984 900 tce, of which 13 161 500 tce was natural gas (94.1% of overall fuel consumption), 799 900 tce — fuel oil (5.7%) and 23 500 tce. — other types of fuel (0.2%).

Main options for modernization

The current five-year power sector modernization programme takes the physical state of heat and electricity generation equipment, existing and prospective electricity and heat load profiles, and tendencies of fuel prices into account, and aims to achieve the least-cost regime of operation of energy objects in the country.

Installation of new, efficient combined-cycle generation equipment in power plants operated at present in Belarus is considered the strategic way to improve the efficiency of electricity and heat generation of Belenergo facilities. .

Other strategic ways aiming to increase the efficiency of operating generation equipment at thermal power plants are:

- Replacement of turbine blades;

- Dismantling of worn-out units and installation of new more efficient units on existing bases;

- Installation of modern generating unit automation control systems;

- Modernization of existing heating plants with installation of steam and gas turbines;

- Replacement of burners.

During 2012-2015 it is planned to continue modernization of the largest power plants in the country — Lukoml and Bereza condensing power plants. These power plants have been in service for more than 35 years, which considerably exceeds their assigned plant life (27 years) and makes their further operation inefficient.

In some cities in Belarus, construction of small combined heat and power (CHP) plants which use domestic fuel resources (primarily wood chips and peat) will be completed in 2012–2015. For instance, a new biomass-firing boiler is to be commissioned in Zhodino CHP plant (60 t/h), a small CHP facility with electrical capacity of 2.7 MW will be built in Pruzhany. .

Construction of hydroelectric power plants is considered one of the most important ways to reduce dependency of Belarus from the import of fossil fuels from the Russian Federation and to reduce greenhouse gases emissions. .

An additional possibility is to use domestic, renewable and secondary energy resources in the power generating facilities. The total volume of these energy resources used by Belenergo for electricity and heat generation was about 274 500 tce in 2010. .

Newly built units are expected to be provided with modern technologies for solid fuel combustion (e. g. fluidized bed technologies), highly efficient systems of ash removal and exhaust gases catalytic reduction.

Energy supply

Natural gas supply and distribution system

At present, all natural gas consumed in Belarus is supplied from the Russian Federation via a well-developed gas transmission pipeline network. The total length of large-size pipelines in Belarus exceeds 7000 km and of the distribution pipelines is about 28 000 km.

Nominal transit capacity of the main pipeline passing through the territory of Belarus Torzhok-Ivatsevichi is 51 billion m3 of gas per year, and the length of the Belarusian part of the Yamal-Europe pipeline is 575 km and its annual capacity equals 33 billion m3 of gas.

Distribution and delivery of natural gas to final consumers in Belarus is performed by Beltransgas which operates:

- More than 6.9 km of large-size pipelines;

- Eight compressor stations with installed electrical capacity of gas compressors equaled 729.7 MW;

- Two underground gas storage facilities, including Osipovichi gas storage with a nominal capacity of 0.36 billion m3 of gas and Pribugskoe gas storage with a capacity of 1.35 billion m3 of gas;

- 218 gas distribution stations with a nominal capacity of 93.4 billion m3 of gas (in 2002, supplies of gas were only 17.6 billion m3);

- 24 gas filling stations and other facilities.

The majority of gas distribution stations are located in Brest (46), Grodno (34) and Minsk (52) regions while other regions of the country receive a more moderate level of gasification due to the remote location from large-size gas transmission pipelines.

In general, the existing system of gas supply can be characterized by a rather low capacity utilization rate of about 20%. This is a legacy of the central planning and design policy of Soviet times when Belarus had low natural gas prices.

In spite of the fact that a considerable overcapacity in the transmission and distribution network exists, the organization of economically feasible gas supply of some regions of Belarus is a challenge because of the lack of necessary pipe-lines.

Development of gas transmission and distribution network is considered one of the key components of the national energy strategy.

Annually, 1350 km of gas transmission and distribution pipelines are built in Belarus. The forecast length of this gas supply network for 2015 is 38 000 km and for 2020 43 000 km.

The existing gas supply network well maintained. Pipelines that have been operating for 15- 25 years account for 15% of the total length, while those operating for 5-15 and less than 5 years account for 47% and 26% respectively. Existing pipeline system provides good basis for reliable gas supply of consumers in Belarus.

Until 2020, priority will be given to the construction of new distribution gas pipelines from existing gas distribution stations to large fuel consumers, primary energy intensive industrial enterprises and dwelling areas.

The gasification of 35 medium and small cities and is expected to be completed and a gas supply infrastructure put into operation for more than 200 000 households by 2020, which will require more than US $140 million.

Two possible scenarios are considered when analysing prospects of the gas supply system development in Belarus.

According to the pessimistic scenario, limited national and foreign financial capabilities may be the main restriction for the further development of the national gas supply network. In this case, the main priority will be given to the construction of new gas supply networks from existing gas distribution stations and reconstruction of gas distribution facilities operated more than 40 years. That will retain considerably switching to natural gas use of some territories, primarily small rural areas and also of dwelling areas.

The optimistic scenario, implies more active participation in the gas network development by both private and State institutions. For this, an active development of the gas supply system in Vitebsk, Gomel, Brest and Minsk regions is forecast. Enhancement of existing piping systems along with the implementation of intensive maintenance and repair programmes for operating facilities and improvement in industrial energy efficiency are expected.

However, comprehensive assessment of possible alternatives regarding more active domestic fuel use as an integral part of the planning and development process of the national gas supply system should be taken into consideration due to energy security concerns and continuously increasing natural gas prices.

Liquefied petroleum gas supply system

Liquefied petroleum gas (LPG) consumption in Belarus has demonstrated a constant decline recently primarily because of its active substitution by natural gas in the housing and utility sector. About 60% of the existing demand for LPG is covered by domestic production, and rest of it is supplied by Russia.

In the forecast period, further decline of LPG consumption is expected.

The use of LPG is economically feasible to meet energy demands of sparsely populated rural areas where construction of natural gas distribution pipelines is not an effective option.

However, possibly LPG use by the transport sector will double. Should the necessary infrastructure be provided, it is possible to considerably increase the use of this energy resource due to its lower demand in housing and utility. The preliminary amount of investment needed would be about US $14.5 million for the construction of new filling stations and the acquisition of special transport and storage tanks.

Oil supply system

At present, Belarus receives all its oil from the Russian Federation via a system of pipelines: Unecha-Polotsk with a transit capacity of 29 million tons of crude per year, Unecha-Mozyr (80 million t per year) and Surgut-Polotsk (40 million t per year). The existing pipeline capacity in Belarus is sufficient to meet both the domestic oil demand and a large part of the oil demand of other European countries.

Electricity and heat

Electricity

Electricity production and consumption in Belarus during 1995–2008 are presented in Table 4 as electricity balance [2].

| 1995 | 2000 | 2001 | 2002 | 2003 | 2004 | 2005 | 2006 | 2007 | 2008 | |

| Electricity produced total | 24.9 | 26.1 | 25.1 | 26.5 | 26.6 | 31.2 | 31.0 | 31.8 | 31.8 | 35.0 |

| - by thermal PP | 24.898 | 26.074 | 25.033 | 26.427 | 26.599 | 31.176 | 30.924 | 31.484 | 31.518 | 35.008 |

| - by hydro PP | 0.020 | 0.027 | 0.030 | 0.028 | 0.028 | 0.034 | 0.036 | 0.035 | 0.035 | 0.039 |

| Electricity imported | 10.1 | 10.0 | 11.0 | 10.0 | 10.8 | 8.0 | 9.1 | 10.1 | 9.4 | 7.1 |

| Electricity consumed total | 32.1 | 33.3 | 33.4 | 33.0 | 33.4 | 34.5 | 35.0 | 36.2 | 36.2 | 36.9 |

| Losses of electricity in grid | 3.6 | 3.4 | 3.5 | 3.4 | 3.4 | 3.6 | 3.6 | 3.8 | 3.7 | 3.7 |

| Electricity exported | 2.9 | 2.8 | 2.7 | 3.5 | 4.0 | 4.7 | 5.1 | 5.8 | 5.1 | 5.2 |

Electricity consumption in Belarus during 2000–2008 grew by 10.8% and in 2008 was 36.9 billion kWh. The most considerable contribution to this growth was made by industry (2.3 bln kWh, or 14% growth) and housing and utilities sector (1.6 bln kWh, or 20% growth). The most intensive growth of electricity consumption took place in 2006.

During 2006, a tendency of more active growth of electricity consumption was monitored. For instance, electricity consumption increased by 4.6% while for the previous year growth was only about 1.5%. Primary fuel consumption in 2006 rose by 6.4% compared to 3% growth in 2005. About 95% of electricity consumed in the country in 2008 was provided by domestic generation facilities, which was almost 17% higher than in 2000. Thus, electricity net import sank almost fourfold during this period.

Heat energy

Heat energy balance during 1995–2008 is presented in Table 5. A tendency of overall heat demand decrease is shown by the data in this table. There are tendencies of a decrease in heat production by boilers and an increase by exhaust heat utilization equipment. Heat consumption is characterized by a weak but stable tendency of a heat demand decrease by household and utility consumers. The tendency of heat loss increasing in pipelines reversed during the 2007–2008 period.

| 1995 | 2000 | 2001 | 2002 | 2003 | 2004 | 2005 | 2006 | 2007 | 2008 | |

| Heat generation total | 72.7 | 69.1 | 73.7 | 71.3 | 72.7 | 72.7 | 73.5 | 74.4 | 69.7 | 67.5 |

| Heat consumption total | 72.7 | 69.1 | 73.7 | 71.3 | 72.7 | 72.7 | 73.5 | 74.4 | 69.7 | 67.5 |

| Heat delivered to household and utilities | 20.3 | 23.6 | 26.8 | 26.5 | 26.7 | 25.3 | 24.4 | 24.5 | 22.3 | 21.0 |

| Heat losses | 3.3 | 4.7 | 5.2 | 5.3 | 5.8 | 6.1 | 6.4 | 6.7 | 6.3 | 6.2 |

Electric power system expansion optimization

Optimization of the electric power system structure has to be an essential part of measures for sustainable development — not only of the energy sector but also the overall economy of a country. Results of research devoted to this problem and carried out at the JINPR-SOSNY of the National Academy of Science (NAS) of Belarus[3] are briefly described below. The WASP IV code was used as an instrument for optimization[4].

The following are the results of recent studies on the optimum electricity source structure made in 2012 (forthcoming for publication). These studies are based mainly on the approach presented in[3]. There are following improvements compared to[3]:

- Recent data on the characteristics of candidate units on natural gas and coal are used for expansion of the power system[5];

- For nuclear units, real data on capital expenditure and cost of nuclear fuel are used from the contractual agreement for the construction of a nuclear power plant (NPP) in Belarus between the Russian Federation and Belarus[6];

- Starting from 2012, the growth rate of nuclear fuel prices is taken as the same as for natural gas.

It should be noted that the data used for the candidate of units on natural gas and coal are from 2009 and are likely to provide a more optimistic view of the traditional energy technologies, since they do not take into account the possible escalation of prices for these technologies by 2012.

Input data for the study included long time electricity demand and system peak power forecasts, prognoses for fuel prices and characteristics of existing and alternative power plants, and schedules for decommissioning and commissioning units regarding the programme of modernization of energy system. New cogeneration power plants were not considered as candidates for expansion of the system because of difficulties with their presentation in the framework of WASP methodology. However, some were estimated from WASP calculations.

The lower forecast of electricity consumption (extrapolated historical data) was used compared to the one previously used from[7]. It is shown in Figure 1. According to the needs of the electricity system, peak power was also less than in[3] and is shown in Figure 2.

The natural gas price prognoses used and shown in Figure 3 were performed using information from[8]. The price of coal in 2012 was adopted on the information from[9]. The price of coal growth rate was assumed to be 2% per year. For nuclear fuel, as mentioned above, the cost is taken from the contractual agreement between the Russian Federation and Belarus for the construction of an NPP in Belarus[6], and the growth rate taken as the same as for natural gas.

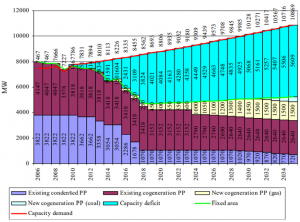

The deficit in the energy system capacity as a result of power source decommissioning and increasing peak power is shown in Figure 4. A 20% reserve of system capacity is taken into account.

Figure 4 shows a gradually retiring from service of energy sources of the existing power system, and newly introduced heat and power for coal and gas. Expansion and reconstruction of cogeneration power plants was estimated regarding of heat demand from WASP calculations. Taking these into account, it can be seen from Figure 4 that optimizing the deficit volume is about 1600 MW in 2015, 4000 MW in 2020, 4500 MW in 2025, 5000 MW in 2030 and 5600 MW in 2035. Characteristics of existing power plants in the Belarus energy system were derived from data provided by experts of BELNIPIENERGOPROM[10].

| Utility | Instal. Capacity, MW | Heat rate, kkal/KW·h | Forced outages, % | Planned outages, d/a | O&M cost | Capital cost, $/kW | Constr. Period,a | Lifetime,a | ||

| Min. load | Average increm. Load | Fixed, $/MWˑh | ||||||||

| Condensed (steam-gas) | 395 | 1859 | 1550 | 0.82 | 28 | 0.9 | 1.53 | 1100 | 3 | 30 |

| Condensed (coal) | 660 | 2335 | 1946 | 0.8 | 35 | 1.84 | 4.95 | 1844 | 4 | 30 |

| Gas turbine | 111 | 3000 | 2646 | 0.55 | 28 | 1.27 | 2.84 | 745 | 1 | 30 |

| NPP | 1170 | 2520 | 2100 | 4.5 | 57 | 4.81 | 6.59 | 3715 | 6 | 50 |

The technologies considered as ‘candidates’ for electricity system expansion to make up the electric power deficit shown in Figure 4 were:

- Condensed power plant using natural gas (steam-gas technology);

- Condensed power plant using coal fuel;

- Gas-turbine power plant;

- NPP 1170 MW capacity.

The characteristics of these candidates are presented in Table 6.

In this study, the base year for discounting of costs is 2012 and the discount rate values 10%. The calculations show that the gas-nuclear scenario is optimal for the development of power generation source structure in Belarus. In this scenario, the first and second NPPs of 1170 MW installed capacity each are introduced in 2018 and 2020. 2028 is optimal for the introduction of a third nuclear unit of the same capacity. Coal units do not fall in the best scenario because of the high capital costs. Although the cost of coal is less than the cost of natural gas, it is not low enough (due to high component of delivery) to compensate for the large capital investments.

The optimized electricity system structure for the gas-nuclear scenario is shown in Figure 5. Energy planning results has demonstrated the cost-effectiveness of few more nuclear units which could be introduction after 2025. However the decision on the introduction of these NPP has not been made yet and the assessment displayed in this report is focused on two NPP units.

The advantage of nuclear scenario is seen also from the comparison of electricity production costs for the scenarios considered. In spite of higher cost in the construction period of nuclear units, the overall cost of electricity production for the nuclear scenario is lower than for the scenario with fossil fuel.

Accordingly, nuclear power generation is considered one of the most promising electricity generation technologies at present. In spite of the serious concerns that arose after the accident at Chernobyl NPP in 1986, the nuclear option proved its competitiveness in comparison with

such traditional technologies as fossil fuel-based or hydro generation. More than 120 nuclear power units have been put into operation in the world since the Chernobyl catastrophe. Today nuclear technology accounts for 16% of the world’s electricity generation, being thus one of the most widespread sources of energy for society.

Such contemporary challenges as global climate change, high dependence on primary energy resources, notable growth in fossil fuels costs and their limited reserves are the main reasons nuclear power development.

Belarus considers implementation of its own nuclear programme one of the key elements of the national long-term energy strategy. High dependence on the import of primary energy, limited economically feasible alternatives for energy supply and high burdens imposed on the national economy by constantly growing fossil fuel costs were the main factors that were taken into consideration to make an appropriate decision.

According to the preliminary calculations, construction of the first 2000 MW Belarusian NPP by 2020 will allow a reduction of annual consumption of fossil fuel (primarily natural gas) for electricity generation by more than five million tce. Nuclear energy will notably change the structure of primary energy consumption in the country, making it more diversified. Nuclear fuel costs were considered another important advantage of a national nuclear programme. It is expected to cover the base load electricity generation and thus decrease the use of much more expensive natural gas for this purpose. The strategic goal is to achieve a share of nuclear power generation in Belarus of 27–29% by 2020.

Construction of the first NPP in Belarus can be considered an important project aimed to fulfil the Republic’s commitments under the Kyoto Protocol and will allow greenhouse emissions to be reduced by 7–10 million tons per year.

The criteria taken into consideration when determining the effectiveness of NPP construction and possible integration into the national power system were:

- High investment needs for NPP construction;

- Technical difficulties related to NPP operation during the night with low electricity demand;

- Limited load following capability of nuclear units;

- Long NPP life that requires long-term optimization (up to 2060) of the Belarusian utility if a nuclear energy programme is launched.

Nuclear energy system to be assessed

The scenario of introducing nuclear energy in Belarus to be assessed is illustrated in Table 7. Complementary to the schedule in the table, one should take into account the possibility of introducing a third nuclear unit after 2020, and units with the same capacity together with the start of decommissioning of units 1 and 2.

The scheme for the nuclear energy system (NES) to be assessed is shown in Figure 6.

Not shown in Figure 6 are the disposal facilities for final storage of operational radioactive waste from the NPP that will also be considered in the NESA.

The current NESA focuses on the domestic facilities and evaluates the non-domestic facilities depending on the availability of data. Also, the assessors intend to perform an assessment of nuclear facilities placed abroad in a comprehensive full-scope NESA, i.e. in the same depth and detail as for domestic facilities.

| Year | Unit 1* 1170 MW(e) VVER AES-2006 |

Unit 2* 1170 MW(e) VVER AES-2006 |

Dry Storage of Spent Fuel (Transportable containers) |

| 2012 | Start of construction | ||

| 2014 | Start of construction | ||

| 2018 | Commissioning | ||

| 2020 | Commissioning | ||

| 2022 | Start of construction | ||

| 2027 | Commissioning | ||

| 2078 | Start of decommissioning | ||

| 2080 | Start of decommissioning | ||

| 2088 | End of decommissioning | ||

| 2090 | End of decommissioning | ||

| 2125 | Decommissioning |

This assessment started end of 2009 with a collection of necessary input data and was completed in the end of 2011 by production of a draft report. During this period Belarus made significant progress in the implementation of its national nuclear energy programme. Information comprised in this report was maintained "up-to-date" by the assessors during the whole assessment period to the extent possible.

However, several important actions were performed in the second half of 2012 which are not considered in this report:

In July 2012, Belarus signed a construction contract with the Russian Federation for two AES-2006 units covering fuel supply, take-back of spent fuel, training and other services.

In October 2012, the IAEA delivered the final report from an IAEA Integrated Nuclear Infrastructure Review (INIR) mission to Belarus. This mission report made 16 general recommendations, and 22 specific recommendations. It concluded that Belarus has made important progress in its development of infrastructure for a nuclear power programme and that Belarus is on its way to being well-prepared with its infrastructure to support the construction of a NPP. To support the INIR mission the draft report on nuclear energy system

assessment (current NESA report) was made available to the INIR mission participants in advance.

In December 2012, Belarus has approved a draft intergovernmental agreement on cooperation in the area of nuclear safety with the Russian Federation.

Finally, a few national documents referred in this report were updated or replaced late in 2012 and early in 2013.

These important actions are to be taken into account while analyzing the results of the assessment of the nuclear energy system of Belarus mainly in the INPRO methodology areas of Infrastructure, Waste Management, Safety and Economics. For example, the assessor stated in several areas – mainly safety and waste management – that he had difficulties to gather necessary information for the assessment. This missing information will be available in the future based on the contractual agreements with the supplier.

At the moment of the report drafting lessons to be learned from Fukushima Daiichi accident in March 2011 were still under discussion. Many of the lessons relevant topics are covered in this report, e.g. regulatory body independence issues, reactor cooling systems including passive systems, seismic issues etc. However a detailed analysis of the implementation of the lessons learned from Fukushima could not be performed within a few months after the accident.

ECONOMICS

In this section, firstly, several important economic parameters are calculated and, secondly, these parameters are then used as input for an assessment of the economics of the Belarus nuclear power project according to the INPRO methodology (as documented in Volume 2 of IAEA-TECDOC-1575 Rev.1, the INPRO Manual) in the context of the planned NES in Belarus.

CALCULATION OF ECONOMIC PARAMETERS

Definition of input data

Input data for a calculation of the main economic parameters are shown in Table 8 for three selected types of power plants that are available in Belarus as future energy sources: two nuclear reactors of the type AES-2006 (VVER-1000) and, as alternative energy sources, four coal fired plants and five gas fired plants. All three power plant types have approximately the same power output. The main sources of these input data are[5] for fossil fuel power plants and the Contract agreement between the Russian Federation and Belarus for the construction of NPP in Belarus[6] as shown in the notes below Table 8. Unmarked data are suggestions by the authors.

| No | Parameters | Units | Power plant | ||

| NPP | Coal | Natural gas | |||

| 1 | Net electric power output | kW(e) | 2 × 1170 | 4 × 660 | 6 × 400 |

| 2 | Construction time | a | 6 | 4 | 3 |

| 3 | Plant lifetime | a | 50 | 30 | 30 |

| 4 | Average load factor | - | 0.9 | 0.85 | 0.85 |

| 5 | Decommissioning cost | mills/kWˑh | 1 | - | - |

| 6 | Overnight cost | $/kW(e) | 4700 | 1175 | 755 |

| 7 | Normalized capital investment schedule (share per year) |

- | 0.020 0.146 0.220 0.244 0.217 0.153 |

0.15 0.3 0.3 0.25 |

0.3 0.5 0.2 |

| 8 | Real discount rate | 1/a | 0.1 | 0.1 | 0.1 |

| 9 | Price per unit of electricity sold | mills/kWˑh | 125 | 125 | 125 |

| 10 | Market income | M$/a | 3600 | 3600 | 3600 |

| 11 | Market share | - | 1 | 1 | 1 |

| 12 | Profit margin | - | 0.12 | 0.12 | 0.12 |

| 13 | Growth time | a | 6 | 4 | 3 |

| 14 | Adjusting coefficient | - | 2.4 | 2.4 | 2.4 |

| 15 | Fixed O&M cost $/kW(e) | 57.7 | 22.0 | 10.8 | |

| 16 | Variable O&M cost | mills/kWˑh | 6.6 | 5.0 | 1.53 |

| 17 | Fuel price | $/GJ | - | 6.14 | 8.97 |

| 18 | Real fuel price annual escalation rate | - | - | 0.02 | 0.02 |

| 19 | Nuclear fuel backend cost | $/kg | 500 | - | - |

| 20 | Spent nuclear fuel average burnup | MWˑd/kg | 55.5 | - | - |

| 21 | Net thermal efficiency of plant | - | 0.352 | 0.442 | 0.555 |

| 22 | Reactor first core average power density | kW/kg | 43.5 | - | - |

| 23 | Natural U purchase cost | $/kg U | 130 | - | - |

| 24 | U conversion cost | $/kg U | 10 | - | - |

| 25 | U enrichment cost | $/kg U | 163 | - | - |

| 26 | Nuclear fuel fabrication cost | $/kg U | 240 | - | - |

| 27 | Number of stages at frontend of fuel cycle | - | 4 | - | - |

| 28 | Time from U purchase till fuel loading | a | -1.5 | - | - |

| 29 | Time from U conversion till fuel loading | a | -1 | - | - |

| 30 | Time from U enrichment till fuel loading | a | -0.75 | - | - |

| 31 | Time from fuel fabrication till loading | a | -0.5 | - | - |

| 32 | Losses at U purchase | - | 0 | - | - |

| 33 | Losses at U conversion | - | 0.005 | - | - |

| 34 | Losses at U enrichment | - | 0 | - | - |

| 35 | Losses at fuel fabrication | - | 0.01 | - | - |

| 36 | First core lowest 235U concentration | - | 0.02 | - | - |

| 37 | First core medium 235U concentration | - | 0.028 | - | - |

| 38 | Refuelling fuel 235U concentration | - | 0.0479 | - | - |

| 39 | Natural 235U concentration | - | 0.00711 | - | - |

| 40 | Enrichment tails 235U conc. | - | 0.0025 | - | - |

As shown in section 1, a gas turbine power plant (GTPP) was also considered as a candidate for the extension of the power system. However, the financial performance of GTPPs is significantly lower than that of the other candidates and is not considered in this section.

Results of economic analysis

Calculations were carried out using the input data defined in Table 8 and a tool of the NESA support package called NEST (NESA economic support tool), which has been provided by IAEA/INPRO group to Belarus.

As proposed in Annex A of Volume 2 of IAEA-TECDOC-1575 (INPRO Manual for Economics), for the three types of plant to be compared in Belarus, the following economic parameters were calculated (Table 9): Levelized unit electricity costs, internal rate of return, return of investment, total investment volume and investment limit.

| Indications | Unit | Abbreviation | Value |

| Levelized unit electricity cost - NPP AES-2006 - Coal PP - Natural gas PP |

cent/kWˑh cent/kWˑh cent/kWˑh |

CN CA1 CA2 |

8.03 9.56 8.79 |

| Internal rate of return - NPP AES-2006 - Coal PP - Natural gas PP |

- - - |

IRRN IRRA1 IRRA2 |

0.159 0.216 0.602 |

| Return of investment - NPP AES-2006 - Coal PP - Natural gas PP |

- - - |

ROIN ROIA1 ROIA2 |

0.223 0.200 0.131 |

| Investment volume/limit - NPP AES-2006 - Coal PP - Natural gas PP |

109$ 109$ 109$ |

INVN INVA1 INVA2 |

11 610/2592 5724/2592 1979/2592 |

The levelized unit electricity cost LUEC consists of three factors, the capital costs, the operation and maintenance costs (O&M), and the fuel costs. LUEC is equivalent to the price of electricity that would have to be paid by consumers to repay exactly all costs for capital, O&M and for fuel supply with a proper discount rate (and without considering profits).

Internal rate of return (IRR) is equivalent to a discount rate that makes the net present value of all cash flows of a particular project equal to zero. The higher a project's IRR, the more attractive it is to undertake the project.

Return on investment (ROI) is frequently derived as the “return” (incremental gain) from an action divided by the cost of that action. Again the higher the ROI the more attractive is the project.

Investment volume is the total investment needed for a project up to the time of commissioning including contingency and owner’s costs. Investment limit is the maximum investment a private company can afford taking into account the (private) market conditions the company is working in.

According to Ref.[13], in the Russian Federation the cost advantage of nuclear against fossil power is even more significant: electricity produced with coal and gas is almost twice as expensive as that generated by an NPP of AES-2006 design.

To confirm the robustness of the calculated levelized unit electricity costs of the selected NPP, robustness indexes were also calculated as specified by the INPRO methodology for economics by simultaneous variation of input parameters of the nuclear and gas power plant such as plant lifetime, average load factor, overnight capital cost, delay of construction, fuel

costs, and gas price escalation rate together with nuclear backend cost and fuel burnup (see Table 10).

| Name of perturbed parameter | Perturbation of NPP data | Perturbation of gas PP data | Abbreviation | Robustness index |

| Plant lifetime | -5% | +5% | RIlifetime | 1.095 |

| Average load factor | -5% | +5% | RILf | 1.051 |

| Overnight cost | +5% | -5% | RICI | 1.059 |

| Construction schedule delay | 1 year | -1 year | RIsch | 1.092 |

| Fuel cost | +5% (nat U cost) | -5% (gas price) | RIUcost | 1.054 |

| Nuclear backend cost | +10% | -10% (gas price escalation rate) | RIBEcost | 1.056 |

| Nuclear fuel burnup | -5% | +5% (Net PP thermal efficiency) | RIburnup | 1.095 |

According to the INPRO methodology, a robustness index of greater than 1.0 indicates sufficient robustness of the economic analysis results, which means that all perturbations studied in Table 10 above show acceptable results.

ASSESSMENT OF ECONOMICS OF BELARUS NUCLEAR ENERGY SYSTEM

Using the results of the economic analyses above, the following economic assessment was performed applying the INPRO methodology as documented in Volume 2 of the report IAEA- TECDOC-1575 Rev.1 (Guidance for the Application of an Assessment Methodology for Innovative Nuclear Energy Systems; INPRO Manual, published November 2008).

The basic principle of the INPRO methodology area of economics reads: Energy and related products and services from innovative NESs shall be affordable and available.

Affordable means that the electricity costs produced by an NPP must be competitive against other available energy sources in the country, and available means that investment in nuclear power must be sufficiently attractive and the risk acceptable.

To check whether the goal of this basic principle is met by the selected NES, INPRO has defined four user requirements that are evaluated below.

User requirement UR1 — cost of energy.

User requirement UR1: The cost of energy from innovative NESs, taking all relevant costs and credits into account, CN, should be competitive with that of alternative energy sources, CA, that are available for a given application in the same time frame and geographic region.

INPRO has defined one criterion CR1.1 (cost competitiveness) that simply repeats what user requirement UR1 asked for: It states that the costs of nuclear energy CN(also called Indicator IN1.1) should be cheaper than the costs of an alternative energy source CA (called Indicator IN1.2) available in the country multiplied by a factor k:

CN < kˑCA

The factor k in criterion CR1.1 is usually taken as 1. A factor k greater than 1 can be used to justify higher costs of nuclear electricity (compared to alternative energy sources) on the basis

of strategic considerations such as an increase of security of supply by diversion of energy sources.

The INPRO methodology recommends using the common approach of the LUEC for determination of energy costs. This approach enables to compare very different energy sources such as nuclear and gas fired plants.

Calculated values of the LUEC for the three selected types of power plants in Belarus were presented in Table 9: the LUEC of nuclear power CN is equal to 8.03 cent/kWh for an NPP with AES-2006 reactors and the LUEC for alternative energy sources CA are 9.56 cent/kWh for a coal fired power plant and 8.79 cent/kWh for a power plant using natural gas as fuel.

Thus, electricity produced by nuclear power is cost competitive against gas and coal fired plant electricity in Belarus under the boundary conditions defined.

Final assessment of user requirement UR1 cost of energy

The advantage of nuclear energy against technology using gas fuel and coal provides the basis to confirm the satisfaction of criterion CR1.1 and, thus, the satisfaction of user requirement UR1 in relation to natural gas and coal, i.e. under the defined boundary conditions (input data in Table 8) nuclear power for electricity generation is cost competitive in Belarus against gas and coal. Criterion CR1.1 can be considered as satisfied.

User requirement UR2 — ability to finance

User requirement UR2: The total investment required to design, construct and commission innovative NESs, including interest during construction, should be such that the necessary investment funds can be raised.

INPRO has developed two criteria for user requirement UR2. Criterion CR2.1 (figures of merit) requires that the investment in an NPP be attractive to an investor compared to an investment in alternative energy sources. Criterion CR2.2 (total investment) defines the maximum investment — based on market conditions — that a private utility can make.

Criterion CR2.1 — financial figures of merit

Criterion CR2.1 states that financial figures of merit for an investment in nuclear power should be at least comparable to or more attractive than those for an investment in alternative energy projects.

INPRO recommends using the internal rate of return (IRR) and the return of investment (ROI) as financial figures of merit. Thus, criterion CR2.1 requires that the IRR and ROI of a nuclear project should be comparable or better than the figures of merit for alternative energy projects.

As shown in Table 9 above, the IRR for an investment in an NPP in Belarus is 0.158, i.e. it is smaller than for power plants with fossil fuel (0.216 for coal and 0.414 for gas). This value of IRR is caused by the significantly higher capital investment for an NPP. It means that energy projects related to fossil fuel are more attractive for private investor than an NPP. Nevertheless, the value of the IRR for an NPP is high enough for the Government to accept the nuclear project, taking into account again strategic considerations such as increased security of supply by diversification of energy sources.

The ROI for a nuclear project (0.223) shows an advantage over projects with coal fuel (0.200, see Table 9) and gas-fired PP (0.090) plants.

Assessment

Criterion 2.1 is partially fulfilled, i.e. investment in the planned nuclear project is better only by criteria ROI compared to investment in gas and coal energy sources. On other criteria, nuclear technology loses to both alternative technologies. However IRR 0.158 for nuclear technology is high enough to be attractive for introduction in Belarus.

Criterion CR2.2— availability of total investment

Criterion CR2.2 states that the total investment needed for a nuclear project should be available to a (private) investor in the country. The value of needed capital for the planned nuclear project in Belarus, as shown in Table 9, is higher than the calculated investment limit. This means that the national utility on its own would not be capable of raising the needed capital by itself, but would need a Government loan.

Assessment

The Belarusian Government is known to ensure the availability of capital through a line of credit from the Russian Federation. Criterion CR2.2, consequently, has been satisfied.

Final assessment of user requirement UR2 — ability to finance nuclear power programme

As not both criteria of UR2 are satisfied, it could be stated that user requirement UR2 is partially satisfied, i.e. the planned nuclear power project is not a sufficiently attractive investment for the government of Belarus from all points of view.

User requirement UR3 — investment risk

User requirement UR3: The risk of investment in innovative NESs should be acceptable to investors taking into account the risk of investment in other energy projects. Satisfaction of this user requirement UR3 is verified by evaluation of criteria CR3.1 (maturity of design), CR3.2 (construction schedule), CR3.3 (robustness) and CR3.4 (political environment).

Criterion CR3.1 — maturity of design

To limit the risk of investment in nuclear power, criterion CR3.1 requires an adequate status of the licensing process, depending on the experience of the country that intends to install an NPP. In the case that the first few NPPs are to be deployed in a country — as in Belarus, intending to install the latest VVER1000 design called AES-2006 as its first NPP — CR3.1 states that nuclear plants of the same basic design should have been constructed and operated in the country of the supplier. At the time the assessment was performed, AES-2006 was licensed in its country of origin and construction projects were ongoing with an AES-2006 type of reactor.

However, the absence of operational experience with NPPs of AES-2006 design in the supplier country (Russian Federation) leads to the conclusion that criterion CR3.1 is currently not yet completely satisfied. The assessor acknowledges that other novel pressurized water reactor (PWR) designs, e.g. EPR, APR-1400 and AP-1000, do not have operational experience in the supplier countries yet, either.

Criterion CR3.2 — construction schedule

To limit the investment risk, criterion CR3.2 requires evidence that the construction schedule (of the nuclear plant type to be installed) considered in the economic analysis has been met in previous construction projects for the same basic design.

As construction of AES-2006 reactors is currently not yet completed, CR3.2 is not fully satisfied (for the same reason as CR3.1), i.e. the absence of experience with construction schedules and operation of this plant type in the supplier country. The assessor acknowledges that also other available novel PWR reactors do not currently have enough experience with construction schedules and operation.

Criterion CR3.3 — robustness

Criterion CR3.3 (robustness) is satisfied if the economic robustness index RI (as defined in Annex A of Volume 2 of IAEA-TECDOC-1575 Rev.1) for selected major input parameters of the planned NES is greater than 1.0. As shown in Table 10, all calculated robustness indexes satisfy this condition within a rather high range of perturbed parameters.

Thus, criterion CR3.3 is fully satisfied.

Criterion CR3.4 — political environment

Criterion CR3.4 stipulates long-term commitment of the national political environment to nuclear power to reduce risk of investment. The Decree [14] of the President of Belarus on the introduction of two nuclear energy units, first in 2016 and second in 2018, confirms the favourable political climate for installation of NPPs in Belarus.

Thus, criterion CR3.4 can be considered as satisfied.

Final assessment of user requirement UR3 — investment risk

This user requirement states that the investment risk into nuclear power should be acceptable in comparison to other available energy projects.

Two factors clearly reduce the risk of investment in nuclear power in Belarus: There is a strong commitment from the Government of Belarus to nuclear power and the economic evaluation demonstrated sufficient robustness of its positive results regarding cost competitiveness.