Environmental Impact of Stressors (Sustainability Assessment)

INPRO basic principle in the area of environmental impact of stressors: The expected adverse environmental

effects of an NES should be well within the performance envelope of current NESs delivering similar energy products.

Contents

- 1 Introduction

- 2 General features of an environmental assessment

- 3 Necessary INPUT for an INPRO assessment in the area of environmental impact of stressors

- 4 INPRO basic principle, user requirements and criteria in the area of environmental impact of stressors

- 4.1 INPRO basic principle: acceptability of expected adverse environmental effects

- 4.2 User requirement UR1: controllability of environmental stressors

- 4.3 User requirement UR2: reduction of total environmental impact of emitted radioactivity

- 4.4 User requirement UR3: optimization of the measures to reduce environmental impact

- 5 Appendix I

Introduction

Objective

This volume of the updated INPRO Manual provides guidance to the assessor of an NES (or a facility thereof)

that is planned to be installed, describing how to apply the INPRO methodology in the area of environmental impact

of stressors. The INPRO assessment should either confirm the fulfilment of all INPRO methodology environmental

CRs, or identify gaps (non-compliance with the INPRO methodology CRs) requiring corrective actions (including

research, development and demonstration (RD&D)) to achieve long term sustainability of the NES assessed.

The INPRO assessor (or team of assessors) is assumed to be knowledgeable in the area of environmental

impact of stressors and/or may be using the support of qualified national or international organizations

(e.g. the IAEA) with relevant experience.

Two general types of INPRO assessor can be distinguished: a nuclear technology holder (i.e. designer,

developer or supplier of nuclear technology) and a (potential) user of such technology. The role of the latter type of

assessor, i.e. a technology user, is primarily to check, in a simplified manner, whether the designer (supplier) has

appropriately taken into account the environmental aspects in the design as defined by the INPRO methodology.

A technology user is assumed to be primarily interested in proven technology to be installed in his or her country in

the near future. A designer (developer) performing an INPRO assessment can use this current publication to check

whether the (innovative) design under development, which is expected to comply with the existing IAEA safety

standards, meets the INPRO methodology environmental requirements for the assessment of sustainability of NES,

and can additionally initiate modifications during early design stages, if necessary, to improve the environmental

performance of the design.

In INPRO sustainability assessment, the term ‘technology user’ does not refer to an independent national

nuclear regulatory authority. INPRO sustainability assessment is most often part of strategic nuclear energy

planning. Typically, this planning activity is performed by national energy ministries, utilities (government or

privately held) and/or their various technical support organizations. In INPRO terminology, the ‘technology user’

is either the country (in a generic sense) or, more specifically, the owner and/or operator of the technology. The

‘technology holder or designer’ is the engineering company (government or privately held) that holds the intellectual

property rights on the technology. When discussing the specific context where trade agreements between countries

restrict or control transfers and uses of technology, the INPRO use of the term ‘technology holder’ may also refer to

the government under which the technology is ‘flagged’.

An assessor in a country embarking on a nuclear power programme has several options when using the

INPRO methodology that depend on the stage of the programme (see the introductory manual of the updated

INPRO methodology).

Every nuclear facility needs an EIA in order to be licensed and to become operational. The INPRO

environmental assessment is not intended to substitute this licensing activity, but should rather demonstrate that the

NES assessed is sustainable in the long term with regard to its environmental impact. Application of the INPRO

methodology cannot substitute fulfilment of any of the existing national requirements in this area. However, INPRO

CR determined in this publication follow the requirements of the IAEA safety standards, in particular, IAEA Safety

Standards Series No. GSR Part 3, Radiation Protection and Safety of Radiation Sources: International Basic Safety

Standards [2].

Scope

Environmental impact from NES involves two large groups of factors. One group impacting the environment

comprises the consumption of non-renewable resources including both fissile/fertile materials necessary to produce

nuclear fuel and other materials (e.g. zirconium). All these factors and consumption of electricity necessary to

construct, operate and occasionally decommission NES installations are considered in the INPRO methodology

manual on environmental impact from depletion of resources [3].

Another group comprises radiological, chemical, thermal and other stressors which NESs release into

environment. This group also includes water intake because this factor can be important for biota even when this

water is returned to the environment in a clean form (e.g. as steam from nuclear power plant cooling towers). All

these factors are considered in this INPRO methodology manual on environmental impact of stressors.

The INPRO methodology in the area of environmental impact of stressors covers only normal operation

and anticipated operational occurrences of NES facilities. Consequences of potential accidents are discussed in

the INPRO methodology manuals in the areas of safety of reactors and safety of the nuclear fuel cycle. Guidance

provided here, describing good practices, represents expert opinion but does not constitute recommendations made

on the basis of a consensus of Member States

Structure

In Section 2, general features of an environmental assessment are presented.

In Section 3, an overview of information that must be available to an INPRO assessor to perform the

environmental assessment is provided.

In Section 4, the background of the INPRO methodology BP for environmental impact of stressors, and the

corresponding URs and CRs, consisting of INs and ALs, are presented. At the CR level, guidance is provided on

how to determine the values of the INs and ALs.

Appendix I provides general information on types of stressor and separate, illustrative lists of stressors

(in the form of tables) for all facilities of an NES based on uranium and mixed oxide (MOX) fuel (as an example).

This appendix could be used by an INPRO assessor as a starting point to generate input for the BP evaluation.

Appendix II presents simplified environmental analysis methods of how to calculate the impact of radiological

stressors, i.e. the dose on humans and non-human biota (plants and animals). It also briefly discusses the calculation

of the impacts of chemical stressors on humans and non-human biota.

Appendix III illustrates the concepts for optimization of the management options for reduction of the

environmental impact of nuclear facilities.

Appendix IV provides basic information on the concept of collective dose, which is used in the INPRO

assessment method described in this publication.

Table 1 provides an overview of the BP, URs and CR in the INPRO methodology area of environmental

impact of stressors.

| INPRO basic principle the area of environmental impact of stressors (acceptability of expected adverse environmental effects): The expected adverse environmental effects of an NES should be well within the performance envelope of current NESs delivering similar energy products. | ||

| INPRO user requirements | Criteria | Indicator (IN) and Acceptance Limit (AL) |

|---|---|---|

UR1: Controllability of environmental stressors: The environmental stressors from each facility of an NES over the complete life cycle should be controllable to levels meeting or below current standards

|

CR1.1: Radiation exposure of the public | IN1.1: Dose to the public |

| AL1.1: Lower than the dose constraint | ||

| CR1.2: Radiation exposure of non-human species | IN1.2: Doses to the reference biota species | |

| AL1.2: Lower than international recommendations | ||

| CR1.3: Impacts of chemicals and other non-radiation environmental stressors | IN1.3: Levels of chemicals and other stressors | |

| AL1.3: Lower than national environmental safety standard levels | ||

UR2: Reduction of total environmental impact of emitted radioactivity:

Total radiotoxicity of radionuclides discharged by the NES assessed should be lower than that of any current NES delivering similar energy products |

CR2.1: Reduction of environmental impact of radiation | IN2.1: Total radiotoxicity of radionuclides emitted to the environment from the NES assessed (RT) |

| AL2.1: RT is lower than the radiotoxicity of stressors emitted to the environment from a current NES delivering similar energy products | ||

UR3: Optimization of the measures to reduce environmental impact:

The measures applied to reduce adverse environmental impact attributable to an NES should be optimized |

CR3.1: Optimization of the measures to reduce environmental impact | IN3.1: Measures to reduce environmental impact of the NES |

| AL3.1: Measures are optimized | ||

Concept of sustainable development and its relationship with the area of environmental impact of stressors of the INPRO methodology

The United Nations World Commission on Environment and Development Report [4] (often known as the Brundtland Report), entitled Our Common Future, defines sustainable development as: “development that meets the needs of the present without compromising the ability of future generations to meet their own needs” (see chapter 2, para. 1 [4]). This definition contains within it two key concepts:

“

- the concept of ‘needs’, in particular the essential needs of the world’s poor, to which overriding priority should be given; and

- the idea of limitations imposed by the state of technology and social organization on the environment’s ability to meet present and future needs.”

Based on this definition of sustainable development, a three part test for any approach to sustainability and

sustainable development was proposed within INPRO project: (i) current development should be fit for the purpose

of meeting current needs with minimized environmental impacts and acceptable economics; (ii) current RD&D

programmes should establish and maintain trends that lead to technological and institutional developments that

serve as a platform for future generations to meet their needs; and (iii) the approach to meeting current needs

should not compromise the ability of future generations to meet their needs.

At first reading, this definition may appear obvious, but when considering the complexities of implemented

nuclear energy technology and systems, plus their many supporting institutions, meeting the three part test is not

always straightforward because many approaches only meet one or perhaps two parts of the test in a given area,

and may fail on the others.

The Brundtland Report overview (para. 61 [4]) of the topic of nuclear energy summarized that:

“After almost four decades of immense technological effort, nuclear energy has become widely used. During this period, however, the nature of its costs, risks, and benefits have become more evident and the subject of sharp controversy. Different countries world-wide take up different positions on the use of nuclear energy. The discussion in the Commission also reflected these different views and positions. Yet all agreed that the generation of nuclear power is only justifiable if there are solid solutions to the unsolved problems to which it gives rise. The highest priority should be accorded to research and development on environmentally sound and ecologically viable alternatives, as well as on means of increasing the safety of nuclear energy.”

The Brundtland Report presented its comments on nuclear energy in chapter 7, section III [4]. In the area of

nuclear energy, the focus of sustainability and sustainable development is on solving certain well known problems

(referred to here as ‘key issues’) of institutional and technological significance. Sustainable development implies

progress and solutions in the key issue areas. Seven key issues are discussed (in this order):

(a) Proliferation risks;

(b) Economics;

(c) Health and environment risks;

(d) Nuclear accident risks;

(e) Radioactive waste disposal;

(f) Sufficiency of national and international institutions (with particular emphasis on intergenerational and

transnational responsibilities);

(g) Public acceptability.

The INPRO methodology for the self-assessment of sustainability and sustainable development of an NES is

based on the broad philosophical outlines of the Brundtland Report’s concept of sustainable development described

above. Twenty-nine years have passed since the publication of the Brundtland Report, and 15 years have passed

since the initial consultancies on development of the INPRO methodology in 2001. In the interim period of time,

significant historical events have starkly highlighted certain key issues. However, the key issues for sustainable

development of NESs have remained essentially unchanged over nearly three decades.

By far the most notable events in the period, which have a direct impact on nuclear energy sustainability, are

related to non-proliferation, nuclear security, cost escalation of new construction and, most notably, the accident at

the Fukushima Daiichi nuclear power plant in 2011. The Fukushima Daiichi accident further clarified that nuclear

safety is an issue of paramount importance for sustainability and that external hazards, associated with a particular

site, could be responsible for a dramatic common cause failure involving multiple reactor units.

In each INPRO methodology manual, a key issue of NES sustainable development is examined. The structure

of the methodology is a hierarchy of INPRO BPs, URs and CRs measuring whether the UR has been achieved.

Under each BP, the CRs include measures that take into consideration the three part test based on Brundtland

Report’s definition of sustainable development which was described above.

This INPRO Manual focuses on the key issue of environmental stressors (radioactive, chemical, heat and

others) associated with NES development and deployment. It does not consider emissions of environmental

stressors under accident conditions. The topics of radioactive and chemical emissions during accidents are covered

under the INPRO areas of safety of reactors and fuel cycle facilities and are published in separate manuals.

In the broad sense of the full related technology chain, NESs are comparatively benign with respect to many

stressor emissions when compared to available, baseload non-NESs. For example, because the waste products

of nuclear fission are contained during all but severe nuclear accidents, releases of radiological species to the

environment from operating nuclear reactors are typically extremely small — at least one and often two or more

orders of magnitude below national regulatory limits and international standards [5]. In fact, radioactive emissions

from coal fired thermal power plants are often higher than for nuclear reactors of comparable scale. This is because

the coal and the resulting fly ash waste contain uranium and thorium oxides and radioactive progenies that are not

fully captured by emission controls. Chemical stressor emissions from nuclear reactors are also very small, whereas

chemical stressors (sulphur oxides, nitrogen oxides (NOX), mercury, dioxins, volatile aromatic hydrocarbons, etc.)

can be significant fugitive components of emissions from coal fired power plants. Although far cleaner than coal,

natural gas fired plants contribute significant emissions of NOX and emissions of methane associated with fuel

leaks. If carbon emissions are considered as an environmental stressor (an increasingly common position globally),

nuclear power is benign and comparable to renewable energy power sources such as hydroelectricity.

Typically, the largest shares of radiological and chemical stressor emissions from NESs originate from

mining, milling and spent fuel reprocessing fuel cycle facilities, as opposed to from nuclear reactors.

One area where nuclear power has similar environmental stressor impacts to other fossil fuel generation

technologies is waste heat rejection. More recently, advances such as supercritical coal and combined cycle natural

gas plants have increased thermal efficiency and thereby reduced the waste heat impacts and cooling water use

per unit of electricity produced by fossil fuel generation technology. However, if evaporative cooling towers are

used, these impacts can often be mitigated in both nuclear and fossil fuel generation technologies. Next generation

nuclear reactors also promise significant increases in thermal efficiency, and certain high temperature plant designs

may allow practical air cooling.

This current INPRO Manual tests whether an NES is sustainable with respect to environmental stressors.

In the case of each NES installation, radiation exposure of the public is compared to the dose constraints. Radiation

exposure of non-human species is compared to the lowest values of international standards or national regulations

(when available). The total radiotoxicity of emissions is also evaluated as a broad metric to consider the reduction

of radiological impact on the environment. Moreover, the manual requests, in UR3, that evidence of optimization

of measures to reduce environmental impact is provided. Suggested optimization approaches include best available

techniques (BATs), best environmental practice (BEP), as low as reasonably achievable (ALARA) or as low as

reasonably practicable (ALARP), with social and economic factors taken into account.

As previously mentioned, environmental stressor impacts tend to be primarily associated with certain fuel

cycle facilities that are not broadly distributed. These facilities are often part of national economies of nuclear fuel

suppliers and service States that provide fuels and services as an export to other national economies. In certain

cases, it may be appropriate to parse available results of environmental assessments of these facilities to consider

separately the fraction of stressor emissions associated with national nuclear power generation and of exported

nuclear fuels and services. The INPRO CRs in this manual are set as total dose constraints and other types of

recommended or required thresholds. The sustainability requirements in the INPRO area of environmental impact

of stressors are fulfilled when all ALs are met, but it is also important to understand the balance of environmental

impacts accepted in exchange for domestic power generation (a broad public good) and in exchange for exported

nuclear fuel products and services (potentially a narrower or broader public good, depending upon the tax/tariff

structures associated with the industry). Understanding this balance is a central question in cost–benefit analysis

(CBA) regarding development of the national NES, which is discussed in the INPRO methodology area of

infrastructure [6].

The NES is expected to meet the three part test based on the Brundtland Report’s definition of sustainable

development if all ALs in all areas are met as outlined in the INPRO methodology.

Protection of the environment is a major consideration in the processes for approving industrial activities in

many countries. The level of societal concern for the environment internationally is clearly indicated in several

documents, in addition to the Brundtland Report [4], reflecting international consensus, notably the Rio Declaration

on sustainable development [7], i.e. the Rio Declaration on Environment and Development, Agenda 21, the Statement

on Sustainable Development of Forests, the United Nations Framework Convention on Climate Change and the

Convention on Biological Diversity. Other related documents are the United Nations resolution on institutional

arrangements for the Implementation of the Global Programme of Action for the Protection of the Marine

Environment from Land-based Activities [8], the Joint Convention on the Safety of Spent Fuel Management and

on the Safety of Radioactive Waste Management [9], the IAEA Convention on Nuclear Safety [10], the Convention

on Environmental Impact Assessment in a Transboundary Context (Espoo Convention) [11], the Convention on the

Prevention of Marine Pollution by Dumping of Wastes and Other Matter (London Convention) [12], the Convention

for the Protection of the Marine Environment of the North-East Atlantic [13] and the European Commission

recommendation on standardized information on radioactive airborne and liquid discharges into the environment

from nuclear power reactors and reprocessing plants in normal operation [14].

Legacy of the past

In some cases, the legacy of the past may still burden the civil nuclear industry (e.g. Refs [15–20]). If the

nuclear industry in general claims its sustainability, this should be achieved for all of its facilities to prevent

objective criticism that may challenge the assertion (e.g. imported uranium used in a sustainable NES should come

from a mining/milling operation that complies with environmental standards at the time that the uranium for the

NES was extracted).

General features of an environmental assessment

This section provides some general background information on environmental issues, particularly on the environmental impact of stressors caused by an NES.

Concept of sustainable development

The concept of sustainability can be considered from several related, but different, points of view:

social, economic, environmental and institutional. This publication deals with the environmental dimension of

sustainability by considering stressors providing adverse impact to the environment.

Protection of the environment is a major consideration in the processes for approving industrial activities in

many countries. The level of international societal concern for the environment is clearly indicated in publications

reflecting international consensus, notably the Brundtland Report [4], the Rio Declaration on sustainable

development [7] and the Joint Safety Convention of the IAEA [9].

The common basic idea in these publications is that the present generation should not compromise the ability

of future generations to fulfil their needs and should leave them with a healthy environment. Nuclear power should

support sustainable development by providing much needed energy with relatively low burdens on the atmosphere,

water, land and resource use. Improvement of the technology should include improvement of its environmental

aspects to a degree that is consistent with importance to society and with the potential environmental performance

of competing technologies.

Interfaces of a nuclear energy system with the environment

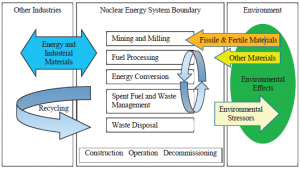

An example of the different components or facilities of a complete NES is presented in Fig. 1, starting with mining and processing, through to the final disposal of nuclear waste.

An NES has several interfaces with the environment and other industries. From the environment, non-renewable resources such as fissile and fertile materials, e.g. uranium and thorium (orange arrow in Fig. 1), are removed and used in the NES, together with other non-renewable materials such as zirconium (bright yellow arrow in Fig. 1). On the other hand, the NES releases some stressors, e.g. radioactive nuclides, that have an adverse impact on the environment (pale yellow arrow in Fig. 1). In addition to these environmental effects, an NES is exchanging with other industries energy and industrial materials required for the installation, operation and finally decommissioning of the nuclear facilities (blue arrow in Fig. 1).

Performance of an environmental analysis

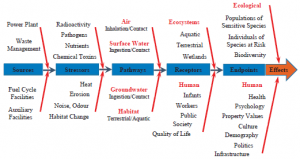

Figure 2 provides a general overview of how to perform an environmental impact analysis in steps.

Starting from the definition of sources, i.e. the facilities of the NES, the stressors from the sources are

identified, the pathways of the stressors to the receptors analysed, leading to the end point of the environmental

analysis, i.e. the impact/effect of the stressors on the recipients. As shown in Fig. 2, Stressors of NES facilities

include radioactive and non-radioactive chemical toxic emissions, heat discharges, noise, impacts on some

non-renewable resources, and water and land use, all with potentially adverse environmental effects, which may

occur on a local, regional or even global scale.

The actual environmental effects attributable to stressors may differ significantly with geographical location

and other site specific and project specific factors of the NES facilities. However, all things being equal, the lower

the level (magnitude) of a stressor, the lower will be the resultant environmental effect. Moreover, the stressors, as

opposed to environmental pathways and receptors, are more under the control of the designers of the NES.

Comparison between nuclear and non-nuclear energy systems

The results of sustainability assessment of NESs in the area of environmental impact of stressors can be used

in comparison with other non-nuclear energy systems only when they both have been analysed to a similar depth.

For example, some environmental stressors (e.g. greenhouse gases) that may be negligible in an NES need to be

kept in the list of stressors, enabling a comparison between different sources of power generation.

Types of stressor in a nuclear energy system

Any energy system will inevitably introduce stressors to the environment, such as release of radionuclides or

non-radioactive chemicals, and depletion of resources, with potentially adverse environmental effects (or impacts)

on a local, regional or even global scale.

The environment is considered to be composed of interacting systems, which, in turn, comprise biological

elements, i.e. fauna and flora, and physical elements, i.e. atmosphere, land, water and resources (e.g. used for

energy production). Impacts are considered to be those effects that alter the existing environment, either temporarily

or permanently.

The adverse environmental impacts usually covered in an EIA as part of the site licensing process include

health effects on people and non-human species. Both radiological and non-radiological (chemical) health effects

are considered. Trade-offs and synergies among the effects from different energy system components and different

environmental stressors are also considered, if possible.

Radionuclides discharged by an NES are stressors that are specific to (but not exclusive to) nuclear power;

in many cases, the public concerns on NES safety are related to the release of radionuclides into the environment.

At the same time, there are many other stressors such as toxic chemicals (e.g. acid mine drainage from waste rock),

heat rejections from once through cooling systems, land use, etc., that, in specific cases, might have a greater

negative impact than radionuclides released into the environment.

Regulatory standards for radiological stressors

For planned exposure situations, which is the case for the environmental INPRO assessments, exposures and risks are subject to control to ensure that the specified dose limits for occupational exposure and those for public exposure are not exceeded, and optimization is applied to attain the desired level of protection and safety. Paragraph 1.22 of GSR Part 3 [2] recommends that dose constraints are to be used “for optimization of protection and safety, the intended outcome of which is that all exposures are controlled to levels that are as low as reasonably achievable, economic, societal and environmental factors being taken into account”. It is further clarified that [2]:

“Dose constraints are set separately for each source under control and they serve as boundary conditions in

defining the range of options for the purposes of optimization of protection and safety. Dose constraints are not dose limits: exceeding a dose constraint does not represent non-compliance with regulatory requirements,

but it could result in follow-up actions.”

Although the dose limits, expressed as an annual effective dose to the representative person, are generally

set at the level of 1 mSv, dose constraints are quite different in different countries (see Table 15, in Section II.2.3).

It should be emphasized that there are no constraints for the release of individual radionuclides. There is

also no international recommendation on the limits for concentrations of radionuclides in the environment. On the

other hand, there are so called reference (or authorized discharge limits [22]) levels for radionuclide discharges into

the environment. These reference levels are facility and site specific, and are the result of environmental analyses

with the objective to identify, with sufficient conservatism, allowable emission rates of radionuclides, so as to not

exceed dose limits.

Primarily, the effective dose to human population/non-human species can be considered as an indicator

of environmental impact of radiation release. Ambient radionuclide concentrations in terms of both individual

radionuclides and total alpha, beta or gamma activity can also be chosen to characterize radionuclides as a stressor

specific to nuclear power (see Table 2).

During normal operation of NES facilities, only small amounts of radioactive materials are released into the

environment, resulting in minor radiological impacts on the general public and the environment, i.e. the regulatory

limits are met with high margins [5].

| Stressors | Parameters characterizing stressors | Units | Models |

|---|---|---|---|

| Radionuclides | Total alpha/beta activity in the environments of interest | Bq/m3 | Ref. [23]/National models |

| Radionuclide activity concentrations in some appropriate media | Bq/m3 | Ref. [23]/National models | |

| Annual effective dose to the population | mSv/a | Ref. [23]/National models | |

| Doses to reference biota species | mGy/a | ERICA, RESRAD-Biota models [24] | |

| Toxic chemicals | Heavy metals | kg/m3 | National models |

| Organic compounds | kg/m3 | National models | |

| Land commitment | Land temporally committed | m2/tU (or GW(e)) | None |

| Land permanently committed | m2/tU (or GW(e)) | None | |

| Particulates | Concentration of particulates released by facility into the air | g/m3 | National models |

| Heat | Heat rejected by a facility per year | MW(th)/a | National models |

| Solids | Concentration of solids dissolved in effluents | g/m3 | National models |

| Concentration solids suspended in water | g/m3 | National models |

Regulatory standards for chemical stressors

In most countries, there are no regulatory limits (standards) for the emission of toxic chemicals into the environment. On the other hand, in most countries there are limits of toxic substances related to their ambient concentrations. Based on such considerations, environmental authorities of some countries establish reference levels for the emission rates of different chemicals, which are evaluated based on analysis of pollutant dispersion using environment models (computer codes).

Examples of stressors

Table 2 presents the NES stressors, the parameters characterizing the stressors that are limited by regulatory requirements and the available analytical models to calculate the impact of stressors.

Necessary INPUT for an INPRO assessment in the area of environmental impact of stressors

This section defines the necessary input and its sources for assessment of an NES in the INPRO methodology area of environmental impact of stressors.

Specification of the nuclear energy system

A prerequisite for INPRO assessment is the specification of the NES (see the introductory manual of the

updated INPRO methodology) to be assessed. The NES is to be defined by the INPRO assessor.

For an environmental assessment, in principle, the following aspects should be covered in the specification

of the NES:

(a) The complete NES should be considered, covering the entire front end of the fuel cycle, the energy conversion unit (reactor) and the entire back end. For all nuclear facilities, the complete lifetime should be covered, i.e. construction, operation and decommissioning.

(b) A global approach should be used, i.e. no geographical boundaries should be introduced that limit the environmental assessment.

(c) If necessary, environmental burdens may be divided into national (or regional) and those occurring outside the country (or regional) borders if such information would be required by stakeholders.

Thus, by meeting the above defined requirements, the general underlying principle of assessing the entirety

of environmental impacts would not be violated.

However, in general, cut-offs, i.e. selection of specific facilities of an NES, will be required in an INPRO

assessment. Such an approach is recommended for nuclear technology users and specifically in the case when a

State is embarking on a nuclear power programme, i.e. in such a country that the INPRO assessment in the area of

environment may consider only the first nuclear power plant and related waste management facilities, assuming

that in the later stages of the nuclear power programme, when more experience is accrued in the country, the scope

of further INPRO assessments will be expanded.

A nuclear technology developer may focus the environmental assessment (analysis) on the design of the

nuclear facility under development.

Information on environmental stressors

An INPRO assessor should have access to relevant design information, i.e. a list of all stressors together with

their levels (e.g. emission rates of radionuclides and chemical toxins, size of land use, etc.), of all NES facilities

to be assessed. This information should be available in design reports. The assessor should further have access

to information on the environmental characteristics of the sites planned for the NES facilities to be assessed.

This information should be available from the responsible government organization or utility.

An INPRO assessor should also have access to the same relevant design information of facilities of an

existing NES that are comparable to the NES facilities to be assessed. Such facilities are called comparable current

facilities in this publication. A comparable current facility means an operating facility of a given type which is

located on a site with environmental characteristics that are comparable to the NES facility assessed and licensed

according to the requirements comparable to the NES facility assessed. For such a comparable current facility,

a complete list of all its stressors and their licensed levels, e.g. emission rates of radionuclides and toxic chemicals,

should be available to the INPRO assessor from the potential supplier. The assessor should also have access to

important environmental characteristics, e.g. wind pattern, population density, etc., and the regulatory requirements

applied for such current facilities. The assessor should further have access to and knowledge of the environmental

standards of the country (or region) where the NES is (planned) to be installed. The national standards should be

available from the responsible government organization (e.g. via its web site). The same information is needed for

the comparable current facilities (if such an approach is planned to be used in the assessment).

The INPRO assessor should also have information to compare the radiotoxicity of release of all radionuclides

of the NES assessed with a current NES delivering similar energy products. For the purpose of the INPRO

assessment, the total radiotoxicity of an NES is defined through dose conversion factors for collective dose per unit

of release, as presented in Ref. [23].

Finally, the INPRO assessor should also have to consider the evidence, e.g. in the form of a written argument

to be provided by the potential supplier, to verify that an optimization procedure such as ALARP has been

performed during the design of all NES facilities to be assessed.

Other sources of INPUT

The INPRO assessor should contact the government organization responsible for environmental aspects to

receive information on the status of EIA studies related to nuclear facilities to be installed in the country as part

of the planned NES. If such studies already exist, most of the necessary input for an INPRO assessment should be

documented in them.

If a State is embarking on a nuclear power programme and using the IAEA service Integrated Nuclear

Infrastructure Review, applying the IAEA milestones approach of Ref. [25], the INPRO assessor should contact

the nuclear energy programme implementing organization responsible for this activity to exchange information and

assure coordination of this effort with the INPRO assessment.

INPRO basic principle, user requirements and criteria in the area of environmental impact of stressors

This section presents the BP, the URs and the CRs in the INPRO methodology area of environmental impact of stressors.

INPRO basic principle: acceptability of expected adverse environmental effects

INPRO basic principle in the area of environmental impact of stressors: The expected adverse environmental

effects of an NES should be well within the performance envelope of current NESs delivering similar energy

products.

Adverse environmental effects may arise from any facility and life cycle stage of an NES. Moreover, the

design and operation of one facility of an NES can have a major influence on the environmental effects of other

facilities. Therefore, in principle, the environmental performance of a proposed NES should be evaluated as an

integrated whole (see the footnote in Section 3.1 on the scope of the INPRO assessment in the area of environmental

impact of stressors).

The BP expresses an expectation that the environmental performance of the NES assessed will be better

than that of a current NES, which is an existing NES comprising facilities of the latest design that is licensed and

operating at the time that the INPRO assessment is performed. A current NES may or may not comply with the

current standards, depending on whether the current standards are different from those that were applied when the

current NES was implemented. However, as further clarified through the first user requirement, UR1, in Section 4.2,

the BP requiring that adverse environmental effects of an NES “should be well within” the performance envelope

of current NES implies, among others, that the expected adverse environmental effects of an NES assessed should

be within the current regulatory standards. Current standards are those prevailing at the time of the INPRO

assessment, and are normally met by recently licensed facilities. In some circumstances, it may be appropriate to

use an environmental standard that is expected to apply when the NES will be implemented.

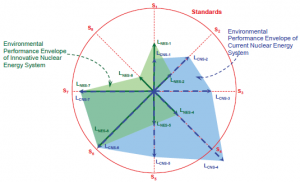

Figure 3 provides some clarification of the BP. Each stressor caused either by an NES to be assessed — called

an “innovative nuclear energy system” in the figure — or by a current NES chosen for comparison, is represented

by a vector whose length is proportional to the level of the stressor, e.g. the release rate of a radioactive nuclide.

The radius of the circle passing along the vector represents the environmental standard for that stressor. In this way,

each stressor can be represented relative to its standard, and all standards will lie on the circumference (red circle

in Fig. 3). The number of stressors illustrated is arbitrary, and the relative magnitude of vectors representing

different stressors has no specific meaning.

Stressors arising from the current NES are shown as blue arrows, and their magnitudes (levels) are denoted

by LCNS-i.

The green arrows represent the stressors arising from an (innovative) NES to be assessed, and their magnitudes

(levels) are denoted by LNES-i. The BP assumes that each of the NES environmental stressors must be located inside

the red circle (i.e. must meet its standard) representing the current standards.

The level of stressors of a current NES may or may not be entirely inside this red circle, depending on

whether the current standards are different from those that were applied when the current NES was implemented,

as illustrated by LCNS-4.

As shown in the figure, some stressors arising from an (innovative) NES to be assessed may have a lower

magnitude (LNES-2, LNES-4, LNES-5) than the current NES, while some of them may be higher (LNES-1) or the same

(LNES-6, LNES-7). In the (innovative) NES to be assessed, some stressors from the current NES may be eliminated

(one is illustrated by LNES-3), while some new stressors (one is illustrated by LNES-8) may occur. Note that neither

the magnitudes of the blue or green areas nor the angles at which the vectors are drawn represent any real quantity,

they are for visualization only.

When all stressors are considered, the performance envelope of an (innovative) NES to be assessed

(green area) should be within the performance envelope of the current NES (blue area).

In case one (or more than one) of the stressors of the (innovative) NES to be assessed compares unfavourably

with the corresponding stressor of the current NES, multivariate analysis might be a possible tool to determine

the degree to which the NES to be assessed is within the current NES environmental performance envelope. An

alternative approach would be to express the level of all stressors commensurately so that they may be accumulated

into a single ‘figure of merit’. Both methods would introduce subjective judgements, but both methods would also

be useful for comparisons of one NES to be assessed to another.

When stressor levels, e.g. dose to the population or ambient concentrations of chemicals, are used as part of a comparison between different NESs, it is important to normalize the stressor levels to per unit energy values. Summarizing the statements above, the BP requires that the spectrum of environmental burdens of an (innovative) NES to be assessed remains within the performance envelope of the current NES (see Fig. 3). Thus, operating technology systems will not be substituted by others that are performing worse, but by technologies that tend to reduce environmental damages instead. The INPRO methodology has defined three user requirements UR1, UR2 and UR3 for the BP.

User requirement UR1: controllability of environmental stressors

User requirement UR1: The environmental stressors from each facility of an NES over the complete life cycle

should be controllable to levels meeting or below current standards.

As stated previously, any energy system will inevitably introduce stressors to the environment, such as

emission of radionuclides or non-radioactive (toxic) chemicals into the air and water, land use and depletion of

non-renewable resources, with potentially adverse environmental effects on a local, regional or even global scale.

UR1 asks that a designer (supplier) of an NES (or a facility thereof) provides controllability of all stressors

throughout the system. Controllability can be achieved by provision of appropriate systems (e.g. filters to reduce

emissions) and monitoring equipment (e.g. instrumentation and control equipment to measure release rates) [26, 27].

The operators of proposed nuclear facilities and processes will be responsible for controlling (and documenting)

the level of stressors during the lifetime of each facility of the NES.

All stressors of an NES facility should be controllable to levels meeting or below current regulatory standards,

i.e. those prevailing at the time the proposed NES is being assessed. In the following, guidance is provided to the

INPRO assessor on how to perform an assessment of CRs related to UR1, assuming the INPRO assessor is a

nuclear technology user planning to install, in their country, nuclear facilities supplied by a nuclear technology

holder.

If an EIA has already been performed for the NES facilities to be assessed and accepted by the authority in

the country as part of the site licensing process, CRs related to UR1 should be automatically met, i.e. no further

application of the INPRO methodology should be needed; however, the INPRO assessor should review the

corresponding reports and confirm that the EIA was performed with due consideration of international guidance

documents (e.g. Refs [28, 29]) and agreements (e.g. Refs [11–13]), and document a summary of the results of this

EIA in the assessment report.

As a guiding objective for the protection of the environment, theoretically, consideration should be given

to the widest possible spectrum of stressors. However, for practical reasons, the degree of inclusion of different

stressors in an INPRO assessment has to be limited.

The first step of determining the level of stressors of an NES facility is to produce a list of all relevant

stressors. For facilities of the front and back end stages of current NESs, an IAEA publication issued in 1996

presents an overview of major stressors, e.g. heavy metal intrusion into surface water and groundwater from mill

tailings and conversion sludge, and mitigation thereof by, for example, effluent treatment [30]. More recent results

of the studies, focused on specific details or new technologies, can be found in the proceedings of conferences or

scientific publications (see Refs [31, 32]).

In Appendix I, examples are provided to the INPRO assessor on which stressors to focus, in the form of tables

that list the important stressors of the facilities of an NES consisting of a water cooled reactor using uranium

oxide (UOX) and MOX fuel. Appendix I also presents brief descriptions of the processes in the individual nuclear

fuel cycle facilities.

Three types of stressor are covered by UR1 and defined in the tables of Appendix I, namely:

- Exposure of the public from radionuclides released to air and/or water (CR1.1);

- Radiation exposure of biota species (CR1.2);

- Other stressors such as ambient concentrations of toxic chemicals to air and/or water, land use, waste heat rejected, dust, etc. (CR1.3).

The media, i.e. water and/or air, and soil, that the stressors are impacting on are listed in the tables of

Appendix I.

Use of a simplified environmental analysis

If an EIA has not yet been performed for the NES facilities to be assessed, it has not yet been accepted

by the regulatory authority or the radiation exposure data of the facility assessed are not available, the INPRO

assessor is offered an option to continue the environmental evaluation of the NES by trying to perform a simplified

(conservative) environmental analysis, as presented in Appendix II, to confirm whether the NES facilities to be

assessed will meet national regulatory standards at their planned site.

Use of a comparable current facility

In some particular situations, the simplified environmental analysis may be avoided for the purpose of INPRO

assessment, even if the EIA has not yet been completed, assuming that the INPRO assessor considers an NES

facility to be based on proven technology. Proven nuclear technology requires that a reference facility — called a

comparable current facility — exists that is licensed based on an EIA and that is in operation. The environmental

behaviour of such a comparable current facility in comparison to the NES facility to be assessed can be used in the

INPRO assessment.

UR1 is satisfied if, in all NES facilities, the levels of all important stressors (listed in Appendix I) are equal

or lower than those of comparable current facilities and, additionally, the NES facility satisfies all of the following

conditions:

- In the NES facilities assessed, no new stressors should appear.

- The environmental characteristics of the NES facility sites should be comparable to the ones of current comparable facilities.

- Comparable regulatory standards should have been (or will be) applied to both the current facilities and the NES facilities to be assessed.

To confirm the existence of a current comparable facility, the INPRO assessor should compare the

environmental characteristics of the planned site of the NES facilities with a site of current facilities. Important

environmental characteristics include, for emissions, the stack height of the plant, the hydrological conditions

(e.g. release into a river, a lake or the ocean), geology (type of soil, aquifers, etc.), meteorology (e.g. wind patterns),

human population distribution around the plant, food chains, endangered species, etc. In principle, all (potential)

sites of nuclear installations have different environmental characteristics. However, if important environmental

characteristics of different sites are comparable, the levels of stressors of facilities located at different sites can be

compared, too. A judgement on the comparability of two sites of nuclear facilities has to be performed by an expert

in the area of EIAs.

The INPRO assessor should perform (with support from an expert in environmental analyses) a comparison

of the regulatory requirements used for licensing of the current facilities and the ones applicable for the NES

facilities to be installed in the country.

If these additional conditions regarding new stressors, comparable environmental characteristics and

regulatory standards are not met, then the proposed approach of using the comparison against comparable current

facility is not applicable.

UR1 explicitly requires to be applied to each facility of the proposed NES, over its complete life cycle (with the exception of potential accidents and their consequences). The INPRO methodology has defined three CRs for UR1, as presented in Table 1.

Criterion CR1.1: Radiation exposure of the public

|

ᅠIndicator IN1.1: Dose to the publicᅠ

|

|---|

|

Dose to a representative person is considered as IN1.1. Depending on the status of the assessed NES deployment, this information may be directly available from the design or licensing documents of the NES to be assessed. If these data cannot be found, a simplified environmental analysis (see Section II.2) should be performed by the assessor. Alternatively, a comparison with a current comparable facility (when applicable) can be used, as described earlier. |

|

ᅠAcceptance limit AL1.1 for dose to the publicᅠ

|

|---|

|

Based on GSR Part 3 [2], regulatory authorities should define dose constraints as outlined in detail in IAEA

Safety Standards Series No. WS-G-2.3, Regulatory Control of Radioactive Discharges to the Environment [33].

A dose constraint should be set up by the regulatory authority for a single facility on a given site, taking into

account local conditions that are relevant for radiological impact on humans. More details on dose constraints are

given in Section II.2.3.

Use of a current comparable facility |

Criterion CR1.2: Radiation exposure of non-human species

|

ᅠIndicator IN1.2: Doses to the reference biota speciesᅠ

|

|---|

|

Current international trends in radiation protection show an increasing awareness of the vulnerability of

the environment. These trends also indicate the need to be able to demonstrate (rather than to assume) that the

environment is protected against the effects of industrial pollutants, including radionuclides, in a wider range of

environmental situations, irrespective of any human connection. The system of protection and safety required by

GSR Part 3 [2] provides a basis for protection from the harmful effects of radiation of both the public and the

environment. This procedure is usually accomplished by means of an environmental assessment that identifies the

target(s), defines the appropriate criteria for protection and assesses the impacts on biota. |

|

ᅠAcceptance limit AL1.2 for doses to the reference biota speciesᅠ

|

|---|

|

In the scientific annexes to the 1996 and 2008 United Nations Scientific Committee on the Effects of Atomic

Radiation (UNSCEAR) reports [38, 39], published data on the exposures and effects on non-human biota have

been evaluated. It has been found that “chronic dose rates of less than 100 μGy·h−1 (2.4 mGy·d−1) to the most

highly exposed individuals would be unlikely to have significant effects on most terrestrial communities” and “that

maximum dose rates of 400 μGy·h−1 (10 mGy·d−1) to a small proportion of the individuals in aquatic populations

of organisms would not have any detrimental effects at the population level”. These values are in agreement with

those reported elsewhere [40, 41], and reflect an international consensus on doses which could be considered as

acceptable for biota species. |

Criterion CR1.3: Impacts of chemicals and other non-radiation environmental stressors

|

ᅠIndicator IN1.3: Levels of chemicals and other stressorsᅠ

|

|---|

|

Radiological impacts in a particular environment constitute only one type of impact, and, in most cases,

may not be the dominant impact of a particular facility or activity. Furthermore, the assessment of impacts on the

environment needs to be viewed in an integrated manner with other features of the protection and safety system

in order to establish the requirements applicable to a particular source. As there are complex interrelations, the

approach to the protection of people and the environment is not limited to the prevention of radiological effects on

humans and on other species. An integrated perspective has to be adopted to ensure the sustainability, now and in

the future, of agriculture, forestry, fisheries and tourism, and of the use of natural resources. |

|

ᅠAcceptance limit AL1.3 for levels of chemicals and other stressorsᅠ

|

|---|

|

For toxic chemicals, the national licensing requirements should be used as AL1.3. For the other stressors

listed in Appendix I, national licensing requirements, e.g. the (normalized) amount of heat rejected to the ultimate

heat sink such as a river or ocean, should be used as AL1.3. |

Final assessment of UR1: Controllability of environmental stressors

The tables in Appendix I can be used by the INPRO assessor to check whether all important stressors of NES

facilities have been considered by the designer.

The acceptance limits AL1.1–AL1.3 of CR1.1–CR1.3 are met if, in all NES facilities, the levels of all

important stressors (listed in Appendix I) are in compliance with existing national or international standards.

User requirement UR2: reduction of total environmental impact of emitted radioactivity

User requirement UR2: Total radiotoxicity of radionuclides discharged by the NES assessed should be lower than

that of a current NES delivering similar energy products.

Radiation tends to be considered as a stressor that is specific to nuclear power, and the concerns of the

ecological safety of the nuclear industry are frequently related to the release of radionuclides into the environment.

As different radionuclides released by nuclear facilities, including waste management facilities, differ in terms

of producing detrimental health or environmental effects, the INPRO methodology suggests using the concept of

radiotoxicity to balance the effects of different radionuclides and to combine them in a single integral parameter.

In its simplest interpretation, radiotoxicity can be defined as the ability of incorporated radionuclides to cause

harmful health effects [42]. This simple definition gives a clear understanding of the basic approach; however, it

cannot be directly applied to the emitted radioactivity, as it does not consider the transport of radionuclides between

the emitter and receptors.

In order to take into account environmental pathways, the INPRO approach is based on application of

dose conversion factors for collective dose per unit activity discharged. The approach considers the discharge of

radionuclides into the atmosphere, freshwater bodies and marine water, thus covering some differences in locations

of nuclear facilities. Hence, radiotoxicity is defined in this publication as an activity of a radionuclide in a release

multiplied by a parameter reflecting a measure of hazard from a given radionuclide.

Although the dose conversion factors (or collective effective dose commitments per unit activity discharged)

are lump parameters, they are based on comprehensive calculations where many environmental transfer parameters

and reference input data for such assessments are included. In particular, the data provided in Ref. [23] are given

for both a simple generic model, which can be used to estimate collective doses for the transfer of radionuclides in

the environment originally developed by UNSCEAR [43], and more complex models, which consider some site

specific factors. To provide comparable bases for assessment of new NESs, generic global parameter values are

used with these models.

For atmospheric releases, three exposure pathways are considered: inhalation, ingestion of terrestrial foods

and external radiation from deposited material. A population density is required in this calculation of collective

dose; for the purposes of calculating screening values, a population density of 35 people per km2 is used [23]. This

represents a global average; considerably higher densities can be found in some countries, while lower densities

can be found in others. The foods considered are: grains, green vegetables and fruit, root vegetables, milk and

meat. Global average yields of particular foods are also required and are taken from the compilation of the Food

and Agriculture Organization of the United Nations (FAO). These are the collective effective dose commitment

values calculated using the effective dose coefficients given in Ref. [23]. In most cases, the values are of the same

order as, or in the range of, the collective doses obtained from the more complex models, and are also presented in

annex VII of Ref. [23].

For releases of radionuclides in liquid form, their dispersion and subsequent transfer to humans will vary

considerably depending on the characteristics of the receiving water body. Although, the general model is used,

account is also taken of the transfer of radionuclides to sediments through the use of the sediment distribution

coefficient Kd. The exposure pathways considered are the consumption of drinking water and aquatic foods.

UR2 explicitly requires to be applied to each facility of the proposed NES, over its complete life cycle, and to

consider the total environmental impact from discharged radioactivity.

The INPRO methodology has defined one CR for UR2, which is presented in Table 1.

Criterion CR2.1: Reduction of environmental impact of radiation

|

ᅠIndicator IN2.1: Total radiotoxicity of radionuclides emitted to the environment from the nuclear energy system assessedᅠ

|

|---|

|

For the purposes of the INPRO assessments, the radiotoxicity Rki,j is defined as the integral activity (Ai,j, in units

of Bq) of radionuclide (i) discharged per GW∙a for each type of release (j) from a given facility (k) multiplied by

the corresponding dose conversion factor for collective dose (DCFi,j , in man Sv/Bq), as given in Ref. [23]: It must be realized that the concept and product of the radiotoxicity assessment used in UR2 (CR2.1) are

different from those required in UR1 (CR1.1). Annual effective dose is used for assessment of the compliance with

radiation safety standards for the public exposure (UR1). Dose conversion factors for the collective effective dose

commitment used for assessments of radiotoxicity are integrated to infinity, providing an IN of the total impact of

the discharge of radionuclides to the environment within UR2. where Nj is the number of radionuclides released to environment j. Then, the total radiotoxicity of the release from the proposed NES (RT) can be calculated by: where M is the number of nuclear facilities that constitute the NES. If only one new facility (e.g. a new nuclear

power plant) is added to an existing NES, the comparison of radiotoxicity should be done only between newly

introduced and former elements of the NESs, as the radiotoxicity of the remainder of the NES remains the same. |

|

ᅠAcceptance limit AL2.1 for total radiotoxicity of radionuclides emitted to the environment from the nuclear energy system assessedᅠ

|

|---|

|

Total radiotoxicity is an integral parameter, and should be calculated based on the releases of all facilities

constituting the NES, i.e. environmental analysis should be performed at the whole NES level. The acceptance

limit AL2.1 of CR2.1 is met if the total radiotoxicity evaluated for the proposed NES is lower than that of any

current NES which provides the same energy products. |

User requirement UR3: optimization of the measures to reduce environmental impact

After confirming that UR1 and UR2 are fulfilled, the next step of an INPRO assessment is to check whether

the NES facility design has been adjusted by the designer (supplier) to provide optimized protection of the

environment.

GSR Part 3 [2] is based on the ten fundamental safety principles stated in IAEA Safety Standards Series

No. SF-1, Fundamental Safety Principles [44]. Fundamental Safety Principle No. 5 of SF-1 [44] requires

optimization of protection and states that “Protection must be optimized to provide the highest level of safety that

can reasonably be achieved.” More specifically, para. 3.24 of GSR Part 3 [2] requires:

“For occupational exposure and public exposure*, registrants and licensees shall ensure that all relevant

factors are taken into account in a coherent way in the optimization of protection and safety to contribute to achieving the following objectives:

(a) To determine measures for protection and safety that are optimized for the prevailing circumstances, with account taken of the available options for protection and safety as well as the nature, likelihood and magnitude of exposures;

(b) To establish criteria, on the basis of the results of the optimization, for the restriction of the likelihood and magnitudes of exposures by means of measures for preventing accidents and for mitigating the consequences of those that do occur.”

“* Requirements for the optimization of medical exposure are specified in paras 3.162–3.177.”

User requirement UR3: The measures applied to reduce adverse environmental impact attributable to an NES

should be optimized.

It is suggested that the principle of pollution prevention [45] should be applied for this purpose by the

designer, i.e. reduction of the amount and level of the stressor produced in the NES is the most favoured means of

reducing potential environmental impacts.

As stated in Section 4.1, the NES to be assessed should be held to higher environmental standards than a current NES. Therefore, UR3:

- Applies the philosophy of achieving the best environmental performance reasonably practicable for an NES facility to be assessed;

- Covers all adverse environmental effects, not only the radiological effects on humans;

- Continues to recognize that costs incurred to enhance environmental performance should not be greatly disproportionate to the achieved benefit.

The INPRO methodology has defined one CR for UR3, which is presented in Table 1.

Criterion CR3.1: Optimization of the measures to reduce environmental impact

|

ᅠIndicator IN3.1: Measures to reduce environmental impact of the nuclear energy systemᅠ

|

|---|

|

There are several options available to the INPRO assessor on how to confirm whether the measures to decrease

the environmental impact of stressors of an NES facility are optimized. This INPRO Manual is not intended

to provide any specific recommendations or indicate preferences on which optimization concept and approach

should be used for such a purpose, and relies instead on regional or national expertise in this area. Possible options

demonstrating optimization of the measures decreasing environmental impact are the BATs, the BEP or the best

available technology not entailing excessive costs (BATNEEC) concepts. Other techniques such as the ALARA or

ALARP concepts can also be used by the designer of an NES facility to demonstrate that measures to provide a

reduction of the environmental impacts are optimized depending on the requirements of national regulations and

experience.

The relationship and differences between the BEP and BATNEEC concepts can be summarized as

follows [47]. BATNEEC is construed to mean the provision and proper maintenance, operation, use and supervision

of facilities which are the most suitable for the purposes. The manner in which this is to be achieved is wide

ranging, but with the overall objective that BATNEEC will be used to limit, abate or reduce an emission from an

activity. The focus is on defined activities, though also addressing areas such as treatment of waste. BEP is more

comprehensive, addressing the entire product life cycle through a combination of practices. These practices may

involve producers, importers, distributors, commercial users and the general public, as well as those engaged in

the collection, recovery or disposal of the substance when it enters the waste stream [47]. Detailed introductory

information on the BAT and BEP methods and an example of application are provided in Section III.2. |

|

ᅠAcceptance limit AL3.1 for optimization of the measures to reduce environmental impactᅠ

|

|---|

|

The acceptance limit AL3.1 of CR3.1 is met if evidence is available to the INPRO assessor that at least one of

the possible optimization approaches was duly applied by the designer of the NES facility assessed. |

Appendix I

Important stressors in nuclear energy systems

Introduction

This appendix, including the tables, is based on Ref. [30]. It presents illustrative lists of important stressors

for facilities of an NES with a water cooled reactor using UOX or MOX fuel.

Important radionuclides, chemicals and other stressors which are relevant for various facilities of an NES

with a water cooled reactor using UOX or MOX fuel are presented in Sections I.2–I.9, based on current experience.

However, it is recommended that, especially, in the case of an innovative design of an NES facility, this list should

be revised based on the actual radionuclide and chemical inventories in the innovative NES facility, their toxicity

and their environmental mobility.

In the case where calculation of the impact of stressors is necessary, it is desirable to maintain a conservative

approach, and to use internationally accepted models, such as those presented in Appendix II, or available licensed

national models. Model descriptions with appropriate references should be documented in the INPRO assessment

report.

The main facilities of an NES with a water cooled reactor using UOX and MOX fuel are as follows: mining

and milling of uranium ore, refining and conversion of uranium ore, enrichment of uranium, fabrication of nuclear

fuel, power generation, reprocessing of nuclear fuel, and radioactive waste storage and disposal including waste

from decommissioning. Some facilities of an NES have greater environmental impacts compared to others; all

facilities have specific stressors and impacts, and therefore each facility should be considered separately. Depending

on the scope of a specific Nuclear Energy System Assessment, only some of the NES facilities could be considered.

It should be mentioned that there are about 200 radionuclides which are specific to the different stages

of the nuclear fuel cycle and the reactor operation and which can cause radiation impacts on the environment.

In the following sections, only relatively long lived radionuclides are mentioned for each facility. However, it

should be recognized that short lived progenies, which are in equilibrium with some parent radionuclides, can

essentially contribute to the doses to public and biota species for many contamination scenarios. Some of these

short lived radionuclides are not discussed here explicitly; however, it is implied that their contributions to doses

have to be taken into account together with the impacts from their parent radionuclides in radiation impact analyses

(e.g. see Appendix II).

Mining of uranium ore

The environmental impacts of mining of uranium ores may involve the disruption of land surface and

water bodies, the release of radionuclides to air and water, the release of heavy metals and acids, the emission of

particulates, etc. In 2011, for example, conventional uranium mining produced 47% of the world’s uranium —

18% from open pits and 29% from underground mines [55]. Non-conventional methods have also been used

for uranium production, such as in situ leaching (ISL), which produced 42% of the world’s uranium in 2011.

The environmental impacts of a uranium mine are potentially numerous and diverse, depending on the mining

technologies used [56].

The environmental impacts of mining activities are measured using several criteria14. Individual dose is

normally used as the criterion for the radiological impact on humans and non-human species. Several other criteria

are used for the non-radiological environmental impact and for the radiological impact on the environment other

than humans.

Usually, baseline studies are conducted before any mining activities are undertaken; these studies are to be

used when establishing environmental quality objectives needed for the construction, operation, decommissioning

and postdecommissioning phases. In other cases, there are pre-established air, sediment, water and groundwater

quality objectives that need to be met. Social, aesthetic, economic and recreational values are met by establishing

requirements to preserve parts of the affected ecosystem, e.g. fish spawning areas and the habitats of endangered

species may need to be preserved for economic or social and ecological reasons.

Radionuclides of concern

Uranium ore contains natural occurring radioactive material (NORM), which includes uranium isotopes (mainly 238U) and uranium progenies (see Fig. 4) such as 230Th and 226Ra. The radioactive decay of the latter nuclides produces 222Rn (an inert gas), which is normally responsible for the biggest part of exposure to workers in the mines and often to the public.

The important radionuclides which have to be considered in the environmental assessment are: 210Pb, 210Po,

226Ra, 222Rn, 228Th, 230Th, 232Th, 234Th, 234U, 235U and 238U. The environmental impact from 227Ac (a decay product

of 235U) is also recommended to be studied. As mentioned above, short lived progenies such as 214Bi and 214Pb

(both progenies of 222Rn, see Fig. 4) are responsible for a large portion of the radiation impact, but are not listed

here because they are always in equilibrium with 222Rn.

For the majority of these radionuclides (except for 222Rn), contamination of water with radionuclides is the

most important exposure pathway. The radioactivity of water is generally stipulated by the dissolved uranium,

thorium, radium and lead ions. However, an aerial pathway can be also important for several radionuclides,

e.g. 226Ra, 230Th and 238U.

Some natural radionuclides, e.g. uranium, provide both radiation and chemical environmental impacts, which

also have to be taken into account in the assessment.

Chemicals of concern

Water contaminated with chemicals (including NORM) is produced by dewatering of underground and open pit mines, surface water runoff from and seepage through the waste rock piles and ore stockpiles, and ISL restoration activities. In situations when the ore includes pyrites, the generation of acid requires neutralization as part of the water treatment process, if this water is planned to be discharged to the environment. Acid generation is a concern of all types of mining because the acid solubilizes and increases the mobility of heavy metals, and for uranium mining, it also mobilizes radionuclides. Utilization of explosives in mining may add some nitrites, nitrates and ammonia to the mine wastewater.

Other stressors

Examples of other stressors are:

- Temporarily committed land, e.g. for a current NES (using an open fuel cycle with light water reactors (LWRs)), this value is estimated to be about 25 ha/GW(e) for open pit mining [30];

- Permanently committed land;

- Dust, originating at exposed ore stockpiles, ore haul roads, etc.

Illustrative list of stressors

An illustrative list of stressors for evaluation of the environmental impact from uranium ore mining is presented in Table 3.

| Stressor | Media type | Normalized release units | Average release units |

|---|---|---|---|

| Radionuclides | |||

| Pb-210 | Water* | MBq/tU or MBq/GW·a | MBq/a or MBq/d |

| Po-210 | Water | ||

| Ra-226 | Air, water | ||

| Ra-228 | Air, water | ||

| Th-228 | Air, water | ||

| Th-230 | Air, water | ||

| Th-232 | Air, water | ||

| Th-234 | Air, water | ||

| U-234 | Air, water | ||

| U-235 | Air, water | ||

| U-238 | Air, water | ||

| Rn-222 | Air | ||

| Ac-227 | Air, water | ||

| Chemicals | |||

| As | Water | kg/tU or MBq/GW·a | kg/a or kg/d |

| Se | Water | ||

| Ni | Water | ||

| Nirites | Water | ||

| Nitrates | Water | ||

| Ammonia | Water | ||

| Sulphates | Water | ||

| Others | |||

| Land temporarily committed | Soil | m2/tU or m2/GW | m2 (total area) |

| Land permanently committed | Soil | ||

| Dust | Air | kg/tU | kg/a |

| Solids dissolved | Water | kg/tU | kg/a |

| Solids suspended | Water | kg/tU | kg/a |

* Water comprises surface water as well as groundwater

Milling of uranium ore

Usually, uranium ore is processed close to the mine to limit transportation costs. The typical process for the

extraction of uranium consists of crushing and grinding of the ore, followed by chemical leaching with sulphuric

acid or an alkali carbonate solution. Acid leaching is the more common method; however, some mills use alkaline

leaching when the ore body contains limestone or similar basic constituents, which would consume uneconomic

quantities of acid. The uranium solution is purified and concentrated by ion exchange and/or solvent extraction

technology. The uranium is then precipitated from solution, filtered and dried to produce a concentrate, known as

yellowcake, which contains between 60% and 90% uranium by weight.

Potential sources of impacts on the environment from mill tailings comprise the following types of release:

(i) escape of gaseous radon; (ii) transport of radioactive particulates by the wind; (iii) contamination of surface

water and groundwater through runoff or seepage of radionuclides, heavy metals or other toxic materials; and

(iv) dispersion of tailings over a wide area caused by erosion or flooding.

Radionuclides of concern