|

|

| (22 intermediate revisions by the same user not shown) |

| Line 1: |

Line 1: |

| | | | |

| | | | |

| − | The INPRO methodology is an IAEA tool that assists Member States in strategic planning and decision making on nuclear power programmes by sustainability assessment of a NES. | + | The INPRO methodology is an IAEA tool that assists Member States in strategic planning and decision making on nuclear power programmes by sustainability assessment of a [[NES]]. |

| − | == Introduction of the INPRO methodology== | + | ==INPRO methodology== |

| | | | |

| | <imagemap> | | <imagemap> |

| | | | |

| − | File:Introduction of INPRO Methodology.png| |center|alt=1| | + | File:Introduction of INPRO Methodology.png|thumb|center|500px|alt=1|Introduction of INPRO Methodology |

| | rect 240 6 315 520 [[Overview_of_the_Methodology_(Sustainability_Assessment)]] | | rect 240 6 315 520 [[Overview_of_the_Methodology_(Sustainability_Assessment)]] |

| | rect 320 135 400 520 [[Safety_of_NFCFs_(Sustainability_Assessment)]] | | rect 320 135 400 520 [[Safety_of_NFCFs_(Sustainability_Assessment)]] |

| Line 17: |

Line 17: |

| | rect 830 195 890 520 [[Proliferation_Resistance_(Sustainability_Assessment)]] | | rect 830 195 890 520 [[Proliferation_Resistance_(Sustainability_Assessment)]] |

| | | | |

| | + | </imagemap> |

| | + | |

| | + | INPRO methodology has been applied several times to the nuclear energy systems based on evolutionary water cooled reactors, as well as sodium cooled fast reactors. The [[NESA]] of Belarus can be seen in [[INPRO Assessment of the Planned Nuclear Energy System of Belarus]], and the [[NESA]] of BN-1200 can be seen in [[Limited Scope Sustainability Assessment of Planned Nuclear Energy Systems Based on BN-1200 Fast Reactors]].<br> |

| | + | |

| | + | =='''''TESTING'''''== |

| | + | ==Introduction== |

| | + | |

| | + | <imagemap> |

| | + | File:Image001.png|right|thumb|210px|Figure 1. Four tasks in INPRO for sustainability of nuclear energy systems. |

| | + | circle 400 400 300 [[Sustainable development]] |

| | + | rect 20 10 200 100 [[Global scenarios]] |

| | + | </imagemap> |

| | | | |

| | + | INPRO derived its concept of a sustainable development of nuclear energy from the United Nations (UN) sustainable development concept issued in the 1987 Report of the World Commission on Environment and Development. The following is the reports definition for sustainable development.<br><br> |

| | | | |

| | + | <big>'''''“Sustainable development is development that meets the needs of the present without compromising the ability of future generations to meet their own needs”.'''''</big> <br><br> |

| | + | |

| | + | A sustainable energy supply is an important requisite for a country to obtain sustainable development. Nuclear energy is one option for sustainable energy supply system. |

| | + | INPRO is an IAEA forward looking project that integrates all areas important to sustainability of nuclear energy. There are four tasks in INPRO for sustainability of nuclear energy systems, as shown in Figure 1; these are global scenarios analysis, role of innovations in sustainability, sustainability assessments and strategies, and outreach and dialogue. Figure 2 captures the essence of INPRO task areas. |

| | + | |

| | + | <imagemap> |

| | + | File:Image00003.png|center|480px|Figure 2. The essence of INPRO task areas. |

| | + | circle 430 430 150 [[Sustainable Nuclear Energy System]] |

| | + | rect 120 320 220 520 [[Assessment]] |

| | + | rect 640 320 740 520 [[Analysis]] |

| | + | rect 330 660 520 780 [[Innovations]] |

| | + | rect 330 100 520 220 [[Planning]] |

| | </imagemap> | | </imagemap> |

| | | | |

| − | == Application of the INPRO methodology==

| + | Based on the UN concept of the sustainable development, INPRO developed the [[INPRO methodology]] for detailed assessment of sustainability of nuclear energy systems. In the INPRO methodology, a nuclear energy system is considered as sustainable if it contributes or at least can contribute to the sustainable development on the national, regional or global level. <br> |

| − | ===Limited Scope Sustainability Assessment of Planned Nuclear Energy Systems Based on BN-1200 fast reactors===

| + | |

| − | ====Introduction====

| + | The INPRO methodology ensures that a given nuclear energy system takes into account the four dimensions of the UN's concept of sustainability: environmental, social, economic and institutional.<br> |

| − | =====Objective=====

| |

| − | This publication provides an example of the limited scope INPRO sustainability assessment of an innovative nuclear energy system using the fast reactor BN-1200 as a case study. The INPRO assessment performed at the full depth criteria level helped to identify actions, including potential research development and demonstration, for sustainable long term deployment of sodium cooled fast reactors.<br>

| |

| − | This publication discusses the application of the INPRO sustainability assessment method to the innovative nuclear energy system based on fast reactor BN-1200 in the areas of economics and safety of nuclear reactors. The case study is intended to verify readiness of the updated INPRO Methodology for assessment of the sodium cooled fast reactors and to develop recommendations for further improvements and updates of the INPRO assessment method.<br>

| |

| − | This publication is intended for use by organizations involved in the development and deployment of the nuclear energy systems including planning, design, modification, technical support and operation for nuclear power plants. Data provided in this publication can be used in further detailed INPRO sustainability assessments of the nuclear energy systems based on BN-1200 reactors, sustainability assessments of other fast reactors and in scenario modelling studies involving fast reactors which can be carried out by the technology holders and technology users.

| |

| | | | |

| − | =====Scope=====

| |

| − | Limited scope INPRO sustainability assessment of sodium cooled fast reactors was performed in 2015-2019 in parallel as a series of bilateral studies between the developers of fast reactors and the IAEA in a few countries developing such reactors. Every study was conducted as a self-assessment exercise performed by the national designer experts focused on their own design and supported by the IAEA staff.<br>

| |

| − | This publication presents the results of the case study of the INPRO assessment of BN-1200 reactor in the INPRO areas of economics and reactor safety. The BN-1200 assessment has been performed by the Russian Federation experts from the Institute of Physics and Power Engineering with the support provided by JSC Afrikantov OKB Mechanical Engineering. It is based on assessors’ experience and publicly available data, taking into account proprietary information concerns.<br>

| |

| − | This INPRO methodology sustainability assessment study is focused on the nuclear power plants that produce primarily electricity, heat or combinations of the two. This publication does not explicitly consider economics and safety issues related to other non-electric applications (hydrogen production, desalination, etc.) or to cogeneration involving such energy products. It is expected that as more detailed information is acquired on the safety of interactions between a reactor and industrial facilities located on the same site, the INPRO criteria and the assessment studies may be modified accordingly.

| |

| | | | |

| − | =====Structure=====

| + | To address specific issues related to the development and deployment of nuclear energy systems (NES) for sustainable energy supply, INPRO has identified six topical areas of relevance to NES sustainability assessment, including economics, environmental impact, safety, proliferation resistance, waste management and infrastructure.<br> |

| − | This publication follows the relationship between the concept of sustainable development and INPRO methodology areas of economics and reactor safety. Section 2 provides general information on the fast reactor development programme in the Russian Federation, to set the context. Section 3 presents the INPRO sustainability assessment of BN-1200 in the area of economics. This includes an overview of the application of the INPRO methodology area of economics to the fast reactors under development, information on the improvement of economic characteristics of sodium cooled fast reactors in the Russian Federation, basic results of analysis and sustainability assessment of BN-1200 in the area of economics. Section 4 presents the INPRO sustainability assessment on the criterion level in the area of reactor safety including assessment of the design robustness, detection and interception of anticipated operational occurrences, design basis accidents, severe plant conditions, independence of levels of defence in depth, inherent safety characteristics, passive safety systems, human factors related to safety and necessary research, development and demonstration. Section 5 summarises the discussion and suggests conclusions on the performed study.

| |

| | | | |

| − | ====General information on the fast reactors considered in the assessment study====

| + | The methodology helps to identify the sustainability related gaps in the existing or planned nuclear energy system. |

| − | Liquid metal cooled fast reactors development programme in the Russian Federation involves the following commercial sodium cooled fast reactors of BN lineage:

| |

| − | *BN-350 prototype reactor constructed and operated (1973-1999) in Kazakhstan;

| |

| − | *BN-600 reactor operated since 1980 as unit 3 of the Beloyarsk NPP, Russian Federation;

| |

| − | *BN-800 reactor operated since 2016 as unit 4 of the Beloyarsk NPP, Russian Federation;

| |

| − | *BN-1200 reactor design; pilot unit is planned to be constructed at the Beloyarsk NPP site as unit 5.

| |

| − | Besides that, this programme includes two more types of the liquid metal cooled fast reactors:

| |

| − | *Lead-cooled fast reactor design concept BREST- OD-300 with on-site manufacturing of nuclear fuel and reprocessing of spent nuclear fuel;

| |

| − | *Lead-bismuth cooled reactor SVBR-100 (installed electrical power rating – 100 MW(e)) which is being developed under the public-private partnership framework.

| |

| − | The associated closed nuclear fuel cycle facilities / technologies have been developed in the Russian Federation:

| |

| − | *MOX fuel experimental fuel assemblies tested in BN-350 and BN-600 reactors (approx. 50 bundles with pellet fuel and approx. 30 bundles with vibro-packed fuel);

| |

| − | *Mining and Chemical Combine (GHK) commercial MOX fuel fabrication facility for BN-800;

| |

| − | *RT-1 spent fuel reprocessing facility (PUREX technology) for uranium oxide fuel from VVER-440 (water cooled reactors) and BN-600;

| |

| − | *Experimental technology for the nitride fuel fabrication;

| |

| − | *Laboratory level technology for the pyrochemical reprocessing of irradiated nuclear fuel.

| |

| − | This INPRO sustainability assessment focuses on BN-1200 reactor as an example case study. In the area of reactor safety, the BN-800 reactor was selected as a reference design for BN-1200 and in a few cases (e.g. references to the accrued operational experience) the BN-600 reactor data have been used. In the INPRO area of economics the BN-800 and BN-600 reactor data have been used for estimation of trends in economic characteristics of BN reactors.<br>

| |

| − | General information on BN-600, -800, -1200 reactors is presented in this section for broader context of the study.

| |

| | | | |

| − | =====BN-600 reactor=====

| + | Innovations help to fill these gaps. The development of both technical and institutional innovations is necessary for nuclear energy to play a sustainable role in the global energy supply. This INPRO activity aims to support the investigation of innovative nuclear energy technologies, related RD&D and institutional arrangements which can be instrumental in developing sustainable nuclear energy system. |

| − | The original plan for the development of BN-600 reactor was based on the following basic assumptions:

| |

| − | *BN-600 would have higher steam temperature and pressure (540°C, 140 MPa) and increased electrical power rating compared to BN-350;

| |

| − | *The original basic concept and layout of BN-600 reactor were originally expected to be similar to BN-350 (loop type reactor);

| |

| − | *The highest electrical power rating of the standard turbo-generators designed for these parameters of steam and available at that time was 200 MW(e). The electrical power rating of BN-600 was defined as 3×200 MW(e). The reactor concept used three completely independent heat transport loops in the secondary and tertiary circuits.

| |

| − | The BN-600 design process modified the original conceptual ideas. Hence, the BN-600 reactor constructed at Beloyarsk NPP site contains significant improvements <ref name=r1> BAKLUSHIN R., Technology of sodium cooled NPP. History of the development and operating experience, (in Russian), SSC RF-IPPE Publ., Obninsk, Russian Federation (2013). </ref> in comparison to the original requirements.<br>

| |

| − | Loop type reactor designs have been broadly used in many countries at the early stages of development of the fast reactors. However, as sodium cooled fast reactor designs grew in installed power rating a loop type layout was revealed to have a number of complicated engineering problems.<br>

| |

| − | Loop type fast reactor designs used relatively long pipelines of large cross section connecting the reactor vessel and intermediate heat exchangers. High temperature and radioactive primary sodium circulating in these pipelines change temperature at changes of reactor power level and creates essential tension/stress loads on the pipes and welds. Compensation of the thermal expansions by bending of the pipelines increases the primary circuit piping length and impedes the primary coolant natural circulation which is important for reactor cooling under the postulated station blackout conditions. Besides that, this does not provide an efficient solution since the mechanical stress in bends may become very close to the yield stress.<br>

| |

| − | Moreover, the main pipeline tension/stress loads compensation forces propagate to the relatively thin walled casings of the pipes, vessels and nozzles occasionally deteriorating their stress-strain characteristics. The areas of the reactor nozzles seemed to be the most vulnerable parts and belonged to the group of most challenging components to fabricate since the stresses caused by the reactor coolant parameter cycles in these locations were the most frequent and the ranges of changing values were broad. Eliminating the nozzles provides an inherent safety feature associated with this hazard and seemed to be the most effective way to increase the robustness of the reactor design. Hence, a high power rating pool type reactor design seemed to have more reliability than a loop type designs.<br>

| |

| − | The electric heating system associated with the primary coolant pipelines and the systems connected to the primary circuit of a loop type reactor had to involve sophisticated and expensive components for large isolating valves and casings of the pipes that cannot be isolated in the case of a leak. This equipment aimed to rule out any dangerous decrease in the reactor sodium level in case of the coolant leakage through the failed pipeline.<br>

| |

| − | More challenges occur implementing fire and radiation protection from the sodium leaks, in particular those caused by the guillotine break of the primary pipeline – an accident scenario postulated to be accounted for by the national regulatory requirements.<br>

| |

| − | Pool type layout has significant advantages compared against loop type sodium cooled fast reactors. The main reactor vessel design can avoid pipeline connections under the normal operation sodium level and accommodation of the primary circuit systems structures and components within the reactor vessel essentially reduces the probability of radioactive sodium leaks to the confinement/ containment premises and makes the solution of leak-tightness problems much easier. The reactor vessel walls, bottom and support structures are designed to withstand mechanical forces caused by the weight of reactor vessel, sodium weight and the weight of reactor internals and fuel. In the pool type design, forces coming from the thermal expansion of reactor pipelines and stressing the reactor vessel nozzles do not exist.<br>

| |

| − | Placing the primary circuit systems, structures and components inside of the reactor vessel reduces the surface-to-volume ratio of the radioactive sodium and the length of welds where in the case of failure a leakage may occur. In addition to the apparently positive safety effects the cost of materials and the reactor fabrication efforts reduce significantly.<br>

| |

| − | In the pool type fast reactor, accommodation of the primary circuit equipment within the large volume of sodium increases the system inertia and makes the system parameters more stable. All internals are immersed in sodium and small sodium leaks through the detachable joints between the reactor internals caused by the pressure difference on different sides can be accepted. Some of the walls of systems, structures and components placed inside the reactor vessel are not required to withstand significant strain, unlike those in the loop type reactors, and can be thinner and/or easier to fabricate. Thinner walls of reactor internals further reduce thermal stresses during the reactor transients.<br>

| |

| − | Elimination of primary circuit pipelines or at least effective minimization of their length essentially reduces the cost of materials used, cost of equipment manufacturing and cost of NPP construction. Sealed compartments of the loop type design primary circuit can be eliminated, reducing the associated costs of ventilation and fire-protection systems, costs of electric heating system, costs of guard casings, thermal insulation and drains. The size and costs of several other systems can be essentially reduced, e.g. the biological shielding is required only for the reactor vessel and a few remaining pipelines and systems containing radioactive sodium. The in-vessel neutron shielding installed in the pool type reactors reduces the radiation dose to the reactor vessel and internals. It also allows for in-vessel spent fuel storage.<br>

| |

| − | Another important feature of the pool type reactor is the possibility of passive removal of the residual heat in emergency situations <ref name=r1> BAKLUSHIN R., Technology of sodium cooled NPP. History of the development and operating experience, (in Russian), SSC RF-IPPE Publ., Obninsk, Russian Federation (2013). </ref>. Passive heat removal depends on natural circulation of the primary and secondary sodium achieved through complex thermal-hydraulic design considerations in the reactor, heat exchangers and steam generators. At the time of BN-600 design development the passive removal of residual heat through the main circuits (three channels) was considered to be reliable.<br>

| |

| − | The deficiencies of pool type designs are mostly related to the size of reactor vessel and to the mass of in-vessel systems, structures and components. Pool type reactor vessels are normally too large to be manufactured at the fabrication facility and transported in one piece to the NPP site. In this situation the reactor vessels need to be manufactured on the site which makes this process more expensive and challenging. The size and mass of reactor can make it vulnerable to the seismic loads and may require special arrangements different from other types of reactors. Other challenges are associated, for example with the introduction of compact and reliable in vessel neutron shielding having sufficiently long lifetime, with the reliable reactor vessel support structure and with the neutron flux monitoring necessary for the NPP power control <ref name=r1> BAKLUSHIN R., Technology of sodium cooled NPP. History of the development and operating experience, (in Russian), SSC RF-IPPE Publ., Obninsk, Russian Federation (2013). </ref>.<br>

| |

| − | Several major concepts have been incorporated in the final design of BN-600 as follows:

| |

| − | *Pool type layout of the primary circuit. This configuration helps to simplify the design, resolve several engineering problems associated with large fast reactors, and provides the designer with conditions and tools which allow both safety improvements and cost reductions;

| |

| − | *New neutron absorbers. New shim rods with higher absorbing efficiency have been installed to compensate fuel burnup effects. It allows an extension of the time between refuelling and improvement of economic characteristics for the plant;

| |

| − | *New design of primary coolant pumps. The primary coolant pumps use a new design with a bottom hydrostatic bearing working under sodium. This design allows control of the pump speed, reduction of the pressure in the reactor vessel gas plenum and further simplification of the layout of the primary and secondary circuits;

| |

| − | *New design of steam generators. Once-through sectional-modular steam generators and sodium-steam reheating scheme provide robustness for the higher temperature and pressures of steam generated in BN-600. In the case of malfunctions of the heat exchanging components the sectional design of steam generators allows isolation of a given section and uninterruptable operation of others;

| |

| − | *Independent heat removal loops in secondary and tertiary circuits. This layout allows for higher flexibility of the operating regimes, e.g. several reactor start-up procedures were performed consecutively and separately in every loop. The reactor can operate at power levels less than 67% of full power using only two pairs of secondary and tertiary loops. Operation of reactor at any power levels with only one pair of secondary and tertiary loops is not allowed.

| |

| − | The BN-600 reactor’s first criticality was achieved in 1980. The power plant unit construction used general civil industrial type building construction requirements. BN-600 has three steam generators PGN-200M, three turbines of the K-200-12.8-3 type and three electric generators of the TGV-200M type. The BN-600 has a thermal power rating of 1470 MW(th) and the electrical power rating amounted 600 MW(e).<br>

| |

| − | The reactor core fuel, blankets, neutron reflectors, the control and protection system including actuators, three primary coolant pumps, most of the primary coolant pipelines, six intermediate heat exchangers and associated structures and components are placed in the main reactor vessel filled with liquid sodium (primary coolant). The volume of primary sodium exceeds 800 m<sup>3</sup>. The BN-600 uses enriched uranium oxide fuel, however it was designed to generate the ‘secondary’ nuclear fuel material (plutonium isotopes) in the reactor core and blankets.<br>

| |

| − | The main reactor vessel is enclosed inside the guard vessel with the gap between these two vessels chosen to keep the sodium level in the main vessel from dropping too low in the case of main reactor vessel leak. The guard vessel sits within a concrete chamber lined with a 10 mm thick steel. The top side of this chamber has a cover of an upper biological shielding.<br>

| |

| − | Each secondary loop includes two intermediate heat exchangers located in the reactor vessel, a buffer tank compensating for sodium volume changes, a secondary coolant pump, pipelines and a sectional-modular steam generator. The volume of secondary sodium in every loop equals 280-300 m<sup>3</sup>.

| |

| | | | |

| − | ===INPRO Assessment of the Planned Nuclear Energy System of Belarus===

| + | INPRO has developed a service for Member States [[“Analysis Support for Enhanced Nuclear Energy Sustainability (ASENES)”]]. The main purpose of this service is to assist and guide Member States on scenario development and analysis, comparative evaluation of nuclear energy system/scenario options and road mapping to support strategic planning towards enhanced nuclear energy sustainability. |

| − | ==References==

| |

| − | {{Reflist}}

| |

The INPRO methodology is an IAEA tool that assists Member States in strategic planning and decision making on nuclear power programmes by sustainability assessment of a NES.

INPRO methodology

Introduction of INPRO Methodology

INPRO methodology has been applied several times to the nuclear energy systems based on evolutionary water cooled reactors, as well as sodium cooled fast reactors. The NESA of Belarus can be seen in INPRO Assessment of the Planned Nuclear Energy System of Belarus, and the NESA of BN-1200 can be seen in Limited Scope Sustainability Assessment of Planned Nuclear Energy Systems Based on BN-1200 Fast Reactors.

TESTING

Introduction

Figure 1. Four tasks in INPRO for sustainability of nuclear energy systems.

INPRO derived its concept of a sustainable development of nuclear energy from the United Nations (UN) sustainable development concept issued in the 1987 Report of the World Commission on Environment and Development. The following is the reports definition for sustainable development.

“Sustainable development is development that meets the needs of the present without compromising the ability of future generations to meet their own needs”.

A sustainable energy supply is an important requisite for a country to obtain sustainable development. Nuclear energy is one option for sustainable energy supply system.

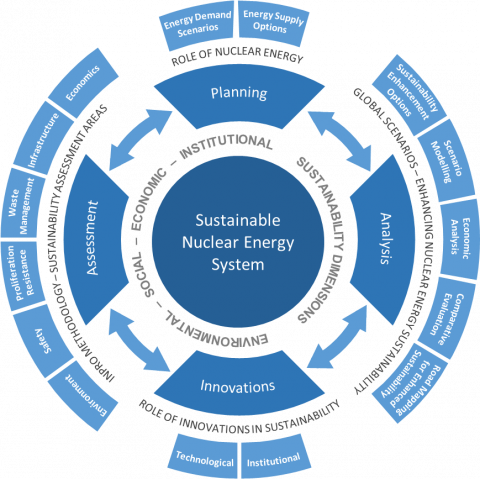

INPRO is an IAEA forward looking project that integrates all areas important to sustainability of nuclear energy. There are four tasks in INPRO for sustainability of nuclear energy systems, as shown in Figure 1; these are global scenarios analysis, role of innovations in sustainability, sustainability assessments and strategies, and outreach and dialogue. Figure 2 captures the essence of INPRO task areas.

Based on the UN concept of the sustainable development, INPRO developed the INPRO methodology for detailed assessment of sustainability of nuclear energy systems. In the INPRO methodology, a nuclear energy system is considered as sustainable if it contributes or at least can contribute to the sustainable development on the national, regional or global level.

The INPRO methodology ensures that a given nuclear energy system takes into account the four dimensions of the UN's concept of sustainability: environmental, social, economic and institutional.

To address specific issues related to the development and deployment of nuclear energy systems (NES) for sustainable energy supply, INPRO has identified six topical areas of relevance to NES sustainability assessment, including economics, environmental impact, safety, proliferation resistance, waste management and infrastructure.

The methodology helps to identify the sustainability related gaps in the existing or planned nuclear energy system.

Innovations help to fill these gaps. The development of both technical and institutional innovations is necessary for nuclear energy to play a sustainable role in the global energy supply. This INPRO activity aims to support the investigation of innovative nuclear energy technologies, related RD&D and institutional arrangements which can be instrumental in developing sustainable nuclear energy system.

INPRO has developed a service for Member States “Analysis Support for Enhanced Nuclear Energy Sustainability (ASENES)”. The main purpose of this service is to assist and guide Member States on scenario development and analysis, comparative evaluation of nuclear energy system/scenario options and road mapping to support strategic planning towards enhanced nuclear energy sustainability.