Difference between revisions of "Safety of NFCFs (Sustainability Assessment)"

| Line 1,940: | Line 1,940: | ||

==See also== | ==See also== | ||

*[[NFCF]] | *[[NFCF]] | ||

| − | *[[Mining and milling of uranium and thorium (Sustainability Assessment)]] | + | *[[Mining and milling of uranium and thorium (Sustainability Assessment)|Mining and milling of uranium and thorium]] |

*[[Uranium refining/conversion and enrichment (Sustainability Assessment)|Uranium refining/conversion and enrichment]] | *[[Uranium refining/conversion and enrichment (Sustainability Assessment)|Uranium refining/conversion and enrichment]] | ||

*[[Uranium_oxide_and_MOX_fuel_fabrication_(Sustainability_Assessment)|Uranium oxide and MOX fuel fabrication]] | *[[Uranium_oxide_and_MOX_fuel_fabrication_(Sustainability_Assessment)|Uranium oxide and MOX fuel fabrication]] | ||

Revision as of 14:30, 6 August 2020

INPRO basic principle (BP) for sustainability assessment in the area of NFCF safety - The planned NFCF is safer than the reference NFCF. In the event of an accident, off-site releases of radionuclides and/or toxic chemicals are prevented or mitigated so that there will be no need for public evacuation.

Contents

- 1 Introduction

- 2 NFCF safety issues related to nuclear energy system sustainability

- 3 Necessary INPUT for a sustainability assessment in the area of safety of nuclear fuel cycle facilities

- 4 INPRO basic principle for sustainability assessment in the area of safety of nuclear fuel cycle Facilities

- 5 Adaptation of the INPRO methodology to uranium and thorium mining and milling

- 5.1 INPRO basic principle for sustainability assessment of uranium and thorium mining and milling facilities in the area of safety

- 5.2 User requirement UR1: Robustness of design during normal operation

- 5.3 User requirement UR2: Detection and interception of AOO

- 5.4 User requirement UR3: Accidents

- 5.5 User requirement UR4: Severe plant conditions

- 5.6 User requirement UR5: Inherent safety characteristics

- 5.7 User requirement UR6: Human factors related to safety

- 5.8 User requirement UR7: RD&D for advanced designs

- 6 Adaptation of the INPRO methodology to a uranium refining/ conversion and enrichment facilities

- 6.1 INPRO basic principle for sustainability assessment of uranium refining/ conversion or enrichment facility in the area of safety

- 6.2 User requirement UR1: Robustness of design during normal operation

- 6.2.1 Criterion CR1.1: Design of normal operation systems

- 6.2.2 Criterion CR1.2: Subcriticality

- 6.2.3 Criterion CR1.3: Facility performance

- 6.2.4 Criterion CR1.4: Inspection, testing and maintenance

- 6.2.5 Criterion CR1.5: Failures and deviations from normal operation

- 6.2.6 Criterion CR1.6: Occupational dose

- 6.3 User requirement UR2: Detection and interception of AOOs

- 6.4 User requirement UR3: Design basis accidents

- 6.5 User requirement UR4: Severe plant conditions

- 6.6 User requirement UR5: Inherent safety characteristics

- 6.7 User requirement UR6 and UR7

- 7 Adaptation of the INPRO methodology to a uranium and MOX fuel production facility

- 7.1 INPRO basic principle for sustainability assessment of fuel fabrication facility in the area of safety

- 7.2 User requirement UR1: Robustness of design during normal operation

- 7.2.1 Criterion CR1.1: Design of normal operation systems

- 7.2.2 Criterion CR1.2: Subcriticality

- 7.2.3 Criterion CR1.3: Facility performance

- 7.2.4 Criterion CR1.4: Inspection, testing and maintenance

- 7.2.5 Criterion CR1.5: Failures and deviations from normal operation

- 7.2.6 Criterion CR1.6: Occupational dose

- 7.3 User requirement UR2: Detection and interception of AOO

- 7.4 User requirement UR3: Design basis accidents

- 7.5 User requirement UR4: Severe plant conditions

- 7.6 User requirement UR5: Independence of DID levels and inherent safety characteristics

- 7.7 User requirement UR6 and UR7

- 8 Adaptation of the INPRO methodology to a reprocessing facility

- 8.1 INPRO basic principle for sustainability assessment of reprocessing facility in the area of safety

- 8.2 User requirement UR1: Robustness of design during normal operation

- 8.2.1 Criterion CR1.1: Design of normal operation systems

- 8.2.2 Criterion CR1.2: Subcriticality

- 8.2.3 Criterion CR1.3: Facility performance

- 8.2.4 Criterion CR1.4: Inspection, testing and maintenance

- 8.2.5 Criterion CR1.5: Failures and deviations from normal operation

- 8.2.6 Criterion CR1.6: Occupational dose

- 8.3 User requirement UR2: Detection and interception of AOOs

- 8.4 User requirement UR3: Design basis accidents

- 8.5 User requirement UR4: Severe plant conditions

- 8.6 User requirement UR5: Independence of DID levels and inherent safety characteristics

- 8.7 User requirements UR6 and UR7

- 9 Adaptation of the INPRO methodology to a storage facility

- 9.1 INPRO basic principle for sustainability assessment of spent nuclear fuel storage facility in the area of safety

- 9.2 User requirement UR1: Robustness of design during normal operation

- 9.2.1 Criterion CR1.1: Design of normal operation systems

- 9.2.2 Criterion CR1.2: Subcriticality

- 9.2.3 Criterion CR1.3: Facility performance

- 9.2.4 Criterion CR1.4: Inspection, testing and maintenance

- 9.2.5 Criterion CR1.5: Failures and deviations from normal operation

- 9.2.6 Criterion CR1.6: Occupational dose

- 9.3 User requirement UR2: Detection and interception of AOOs

- 9.4 User requirement UR3: Design basis accidents

- 9.5 User requirements UR4 – UR7

- 10 See also

- 11 References

Introduction

Objective

This volume of the updated INPRO manual provides guidance to the assessor of a planned NES (or a facility) on how to apply the INPRO methodology in the area of NFCF safety. The INPRO assessment is expected either to confirm the fulfilment of all INPRO methodology NFCF criteria, or to identify which criteria are not fulfilled and note the corrective actions (including RD&D) that would be necessary to fulfil them. It is recognized that a given Member State may adopt alternative criteria with indicators and acceptance limits that are more relevant to its circumstances. Accordingly, the information presented in Chapters 5 to 10 (INPRO methodology criteria, user requirements and basic principle for sustainability assessment in the area of safety of NFCFs) should be viewed as guidance. However, the use of such alternative criteria should be justified as providing an equivalent level of enhanced safety as the INPRO methodology.

This report discusses the INPRO sustainability assessment method for the area of safety of NFCFs. The INPRO sustainability assessment method for safety of nuclear reactors is discussed in a separate report of the INPRO manual .

This publication is intended for use by organizations involved in the development and deployment of a NES including planning, design, modification, technical support and operation for NFCF. The INPRO assessor (or a team of assessors) is assumed to be knowledgeable in the area of safety of NFCFs and/or may be using the support of qualified national or international organizations (e.g. the IAEA) with relevant experience. Two general types of assessors can be distinguished: a nuclear technology holder (i.e. a designer, developer or supplier of nuclear technology), and a (potential) user of such technology. The role of a technology user in an INPRO assessment is to check in a simplified way whether the supplier’s facility design appropriately accounts for nuclear safety related aspects of long term sustainability as defined by the INPRO methodology. A designer (developer) can use this guidance to check whether a new design under development meets the sustainability focused INPRO methodology criteria in the area of fuel cycle safety and can additionally initiate modifications during early design stages if necessary to improve the safety level of the design. The current version of the manual includes a number of explanations, discussions, examples and details so it is deemed to be used by technology holders and technology users.

Scope

This manual provides guidance for assessing the sustainability of a NES in the area of NFCF safety. This report deals with NFCFs that may be potentially involved in the NES, i.e. mining, milling , refining, conversion, enrichment, fuel fabrication, spent fuel storage, and spent fuel reprocessing facilities. It is clear that operations of NFCFs are more varied in their processes and approaches than are nuclear reactor systems. Most significant of these variations is the fact that some countries pursue an open fuel cycle, i.e. spent fuel is treated as a waste, while some others have a policy of closing the fuel cycle, i.e. treating the spent fuel as a resource, and a number of states have yet to make a final decision on an open or closed fuel cycle. Further, diversity is large if one considers different types of fuels used in different types of reactors and the different routes used for processing the fuels before and after their irradiation depending upon the nature of the fuel (e.g. fissile material: low enriched uranium/ natural uranium/ uranium-plutonium/ plutonium/ thorium; fuel form: metal/ oxide/ carbide/ nitride) and varying burnup and cooling times. Taking into account this complexity and diversity, the approach adopted in this report has been to deal with the issues as far as possible in a generic manner, rather than describing the operations that are specific to certain fuel types. This approach has been chosen in order to arrive at a generalized procedure that enables the user of this report (the assessor) to apply it with suitable variations as applicable to the specific fuel cycle technology being assessed. In addition, it is recognized that the defence in depth (DID) approach and ultimate goal of inherent safety form the fundamental tenets of safety philosophy. The DID approach is applied to the specific safety issues of NFCFs.

As the safety issues relevant to the sustainability assessment of refining and conversion facilities are similar to those of enrichment facilities, the INPRO methodology criteria for those two types of facilities are combined in this manual and not discussed separately. Based on similar considerations, the assessments of uranium and uranium-plutonium mixed oxide (MOX) fuel fabrication facilities have likewise been combined . However, particular care must be taken to ensure that using a graded assessment approach and enhanced safety measures for higher risk facilities (e.g. using plutonium or uranium with higher enrichments/criticality risks) will yield appropriately enhanced levels of safety.

It should be noted that for NFCFs the INPRO methodology includes the consideration of chemical and industrial safety issues, principally where these could affect facility integrity or radiological safely. Although otherwise beyond the scope of this guidance, it bears noting that care is required due to the different public perceptions of the risks posed by conventional and radiological events and releases and, conversely, the negative reactions that may be generated about an NFCF’s radiological safety if conventional safety events occur.

In the current version of the INPRO methodology, the sustainability issues relevant to safety of reactors and safety of NFCFs are considered in different areas. Innovative integrated systems combining reactors, fuel fabrication and reprocessing facilities on the same site such as molten salt reactors with nuclear fuel in liquid form and integrated fast reactors with metallic fuel has not been specifically addressed. Reactor and NFCF installations of such integrated systems are expected to be assessed simultaneously and independently against corresponding criteria in the INPRO areas of reactor safety and safety of NFCFs. When more detailed information on the safety issues in integrated systems has been acquired, this approach can be changed in the next revisions of the INPRO methodology.

NFCFs processing nuclear materials in a given stage of the fuel cycle may be based on different technologies with different safety issues. Different kinds of fuel may be fabricated or reprocessed in different facilities serving different reactors. In this report, the discussion is restricted to the fabrication of fuels most commonly used in power reactors; however, the requirements and criteria have been formulated in a sufficiently generic manner and are therefore expected to be applicable to innovative technologies. Nevertheless, the fabrication or reprocessing technologies for innovative types of fuels (e.g. TRISO fuel with carbon matrix, metal fuel, nitride fuel) may involve safety issues requiring the modification of specific INPRO methodology criteria or the introduction of new or complementary criteria. It is expected that the future accrual of more detailed information on safety issues in innovative NFCFs will give rise to proposed modifications of the INPRO criteria and that these will be considered in future revisions of the methodology.

In this version of the INPRO methodology, the transportation of fresh nuclear fuel, spent nuclear fuel, and other radioactive materials or wastes throughout the nuclear fuel cycle has not been generally considered as independent stages of the nuclear fuel cycle. The INPRO methodology does not define specific requirements and criteria for such transportation but assumes that the safety issues of transportation are to be considered as part of the INPRO assessments of those NFCFs from which such packaging and transportation activities originate, e.g. fuel fabrication facilities for fresh fuel transportation and spent fuel storage facilities for spent fuel transportation. The IAEA has developed a set of safety standards to establish requirements and recommendations that need to be satisfied to ensure safety and to protect persons, property and the environment from the effects of radiation in the transport of radioactive material[1][2][3][4][5][6].

This manual does not establish any specific safety requirements, recommendations or criteria. The INPRO methodology is an internationally developed metric for measuring nuclear energy system sustainability and is intended for use in support of nuclear energy system planning studies. IAEA safety requirements and guidance are only issued in the IAEA Safety Standards Series. Therefore, the basic principles, user requirements and associated criteria contained in the INPRO methodology should only be used for sustainability assessments. The INPRO methodology is typically used by Member States in conducting a self-assessment of the sustainability and sustainable development of nuclear energy systems. This manual should not be used for formal or authoritative safety assessments or safety analyses to address compliance with the IAEA Safety Standards or for any national regulatory purpose associated with the licensing or certification of nuclear facilities, technologies or activities.

The manual does not provide guidance on implementing fuel cycle safety activities in a country. Rather, the intention is to check whether such activities and processes are (or will be) implemented in a manner that satisfies the INPRO methodology criteria, and hence the user requirements and the basic principle for sustainability assessment in the area of safety of NFCFs.

Structure

This publication follows the relationship between the concept of sustainable development and different INPRO methodology areas. Section 2 describes the linkage between the United Nations Brundtland Commission’s concept of sustainable development and the IAEA’s INPRO methodology for assessing the sustainability of planned and evolving NESs. It further describes general features of NFCF safety and presents relevant background information for the INPRO assessor. Section 3 identifies the information that needs to be assembled to perform an INPRO assessment of NES sustainability in the area of NFCF safety. Separate page NFCF identifies the different types of facilities that can form part of a nuclear fuel cycle. This page also provides an overview of the general safety aspects of those facilities. Section 4 presents the rationale and background of the basic principle and user requirements for sustainability assessment in the INPRO methodology area of NFCF safety. Criteria are then presented in Sections 5 to 9 along with a procedure at the criterion level for assessing the potential of each NFCF to fulfil the respective INPRO methodology requirements. The Annex presents a brief overview of the selected IAEA Safety Standards for NFCFs that are the basis of the INPRO methodology in this area. The Annex also explains the relationship and differences between the IAEA Safety Standards and the INPRO methodology. Table 1 provides an overview of the basic principle and user requirements for sustainability assessment in the area of NFCF safety.

| INPRO basic principle for sustainability assessment in the area of NFCF safety: The planned NFCF is safer than the reference NFCF. In the event of an accident, off-site releases of radionuclides and/or toxic chemicals are prevented or mitigated so that there will be no need for public evacuation. | |

| UR1: Robustness of design during normal operation | The assessed NFCF is more robust than the reference design with regard to operation and systems, structures and components failures. |

| UR2: Detection and interception of AOOs | The assessed NFCF has improved capabilities to detect and intercept deviations from normal operational states in order to prevent AOOs from escalating to accident conditions. |

| UR3: Design basis accidents (DBAs) | The frequency of occurrence of DBAs in the assessed NFCF is reduced. If an accident occurs, engineered safety features and/or operator actions are able to restore the assessed NFCF to a controlled state, and subsequently to a safe state, and the consequences are mitigated to ensure the confinement of radioactive and/or toxic chemical material. Reliance on human intervention is minimal, and only required after sufficient grace period. |

| UR4: Severe plant conditions | The frequency of an accidental release of radioactivity into the environment is reduced. The source term of accidental release into the environment remains well within the envelope of the reference facility source term and is so low that calculated consequences would not require public evacuation. |

| UR5: Independence of DID levels and inherent safety characteristics | An assessment is performed to demonstrate that the DID levels are more independent from each other than in the reference design. To excel in safety and reliability, the assessed NFCF strives for better elimination or minimization of hazards relative to the reference design by incorporating into its design an increased emphasis on inherently safe characteristics. |

| UR6: Human factors (HF) related to safety | Safe operation of the assessed NFCF is supported by accounting for HF requirements in the design and operation of the facility, and by establishing and maintaining a strong safety culture in all organizations involved in the life cycle of the facility. |

| UR7: RD&D for advanced designs | The development of innovative design features of the assessed NFCF includes associated research, development and demonstration (RD&D) to bring the knowledge of facility characteristics and the capability of analytical methods used for design and safety assessment to at least the same confidence level as for operating facilities. |

This section presents the relationship of the INPRO methodology with the concept of sustainable development, a comparison of NFCFs with chemical plants and nuclear reactors, and a summary of INPRO recommendations on the application of the DID concept to NFCFs.

The concept of sustainable development and its relationship with the INPRO methodology in the area of NFCF safety

The United Nations World Commission on Environment and Development Report [7](often called the Brundtland Commission Report), defines sustainable development as “development that meets the needs of the present without compromising the ability of future generations to meet their own needs” (para.1). Moreover, this definition:

“contains within it two key concepts:

- the concept of ‘needs’, in particular the essential needs of the world’s poor, to which overriding priority should be given; and

- the idea of limitations imposed by the state of technology and social organization on the environment’s ability to meet present and future needs.”

Based on this definition of sustainable development a three-part test of any approach to sustainability and sustainable development was proposed within the INPRO project: 1) current development should be fit to the purpose of meeting current needs with minimized environmental impacts and acceptable economics, 2) current research, development and demonstration programmes should establish and maintain trends that lead to technological and institutional developments that serve as a platform for future generations to meet their needs, and 3) the approach to meeting current needs should not compromise the ability of future generations to meet their needs.

The definition of sustainable development may appear obvious, yet passing the three-part test is not always straightforward when considering the complexities of implemented nuclear energy systems and their many supporting institutions. Indeed, many approaches may only pass one or perhaps two parts of the test in a given area and fail the others. Where deficiencies are found, it is important that appropriate programmes be put in place to meet all test requirements to the extent practicable. Nevertheless, in carrying out an NFCF INPRO assessment, it may be necessary to make judgements based upon incomplete knowledge and to recognize, based upon a graded approach, the variable extent of the applicability of these tests for a given area.

The Brundtland Commission Report’s overview (para.61 in Ref[7]) on nuclear energy summarized the topic as follows:

The Brundtland Commission Report presented its comments on nuclear energy in Chapter 7, Section III. In the area of nuclear energy, the focus of sustainability and sustainable development is on solving certain well known problems (referred to here as ‘key issues’) of institutional and technological significance. Sustainable development implies progress and solutions in the key issue areas. Seven key issues are discussed:

- Proliferation risks;

- Economics;

- Health and environment risks;

- Nuclear accident risks;

- Radioactive waste disposal;

- Sufficiency of national and international institutions (with particular emphasis on intergenerational and transnational responsibilities);

- Public acceptability.

The INPRO methodology for self-assessing the sustainability and sustainable development of a NES is based on the broad philosophical outlines of the Brundtland Commission’s concept of sustainable development described above. Although three decades have passed since the publication of the Brundtland Commission Report and eighteen years have passed since the initial consultancies on development of the INPRO methodology in 2001 the definitions and concepts remain valid. The key issues for sustainable development of NESs have remained essentially unchanged over the intervening decades, although significant historical events have starkly highlighted some of them.

During this period, several notable events have had a direct bearing on nuclear energy sustainability. Among these were events pertaining to non-proliferation, nuclear security, waste management, cost escalation of new construction and, most notably, to nuclear safety.

Each INPRO methodology manual examines a key issue of NES sustainable development. The structure of the methodology is a hierarchy of INPRO basic principles, INPRO user requirements for each basic principle, and specific INPRO criteria for measuring whether each user requirement has been met. Under each INPRO basic principle for the sustainability assessment of NESs, the criteria include measures that take into consideration the three-part test based on the Brundtland Commission’s definition of sustainable development as described above.

The Commission Report noted that national governments were responding to nuclear accidents by following one of three general policy directions:

“National reactions indicate that as they continue to review and update all the available evidence, governments tend to take up three possible positions:

- remain non-nuclear and develop other sources of energy;

- regard their present nuclear power capacity as necessary during a finite period of transition to safer alternative energy sources; or

- adopt and develop nuclear energy with the conviction that the associated problems and risks can and must be solved with a level of safety that is both nationally and internationally acceptable.”

These three typical national policy directions remain consistent with practice to the current day. Within the context of a discussion on sustainable development of nuclear energy systems, it would seem that the first two policy positions cannot result in development of a sustainable nuclear energy system in the long term since nuclear energy systems are either avoided altogether or phased out over time. However, it is arguable that both policy approaches can meet the three-part Brundtland sustainable development test if technology avoidance or phase-out policies are designed to avoid foreclosing or damaging the economic and technological opportunity for future generations to change direction and start or re-establish a nuclear energy system. This has certain specific implications regarding long term nuclear education, knowledge retention and management and with regard to how spent nuclear fuels and other materials, strategic to nuclear energy systems, are stored or disposed of.

The third policy direction proposes to develop nuclear energy systems that “solve” the problems and risks through a national and international consensus approach to enhance safety. This is a sustainable development approach where the current generation has decided that nuclear energy is necessary to meet its needs, while taking a positive approach to develop enhanced safety to preserve the option in the future. In addition to the general outlines of how and why nuclear reactor safety is a principal key issue affecting the sustainability and sustainable development of nuclear energy systems, the Commission Report also advised that several key institutional arrangements should be developed. Since that time, efforts to establish such institutional arrangements have achieved a large measure of success. The Brundtland Commission Report was entirely clear that enhanced nuclear safety is a key element to sustainable development of nuclear energy systems. It is not possible to measure nuclear energy system sustainability apart from direct consideration of certain safety issues.

Understanding the psychology of risk perception in the area of nuclear safety is critical to understanding NES sustainability and sustainable development. In a real measured sense, taking into account the mortality and morbidity statistics of other non-nuclear energy generation technology chains (used for similar purpose), nuclear energy has an outstanding safety record, despite the severe reactor accidents that have occurred. However, it should not be presumed that this means that reactor safety is not a key issue affecting nuclear energy system sustainability. How do dramatically low risk estimations (ubiquitous in nuclear energy system probabilistic risk assessment) sometimes psychologically disguise high consequence events in the minds of designers and operators, while the lay public perception of risk (in a statistical sense) may be tilted quite strongly either toward supposed consequences of highly unlikely, but catastrophic disasters, or toward a complacent lack of interest in the entire subject? This issue has been studied for many years. What should be the proper metrics for the INPRO sustainability assessment methodology given that the technical specialist community has developed an approach that may seem obscure and inaccessible to the lay public?

With regard to nuclear safety, the public are principally focussed on the individual and collective risks and magnitude of potential consequences in case of accidents (radiological, economic and other psychosocial consequences taken together). In the current INPRO manual, the URs and CRs focus on assessment of the NES characteristics associated with the majority of these issues. Unlike several other key sustainability issues assessed in other areas of the INPRO methodology, Brundtland sustainability in the area of nuclear safety is intimately tied to public perception of consequence and risk. Continuously allaying public concern about nuclear reactor safety is central to sustainability and sustainable development of nuclear energy systems.

This report describes how to assess NES sustainability with respect to the safety of NFCFs.

How NFCFs compare with nuclear reactors and chemical plants

As stated in Section 3 of Ref[8], NFCFs imply a great diversity of technologies and processes. They differ from nuclear power plants (NPPs) in several important aspects, as discussed in the following paragraphs.

First, fissile materials and wastes are handled, processed, treated, and stored throughout NFCF mostly in dispersible (open) forms. Consequently, materials of interest to nuclear safety are more distributed throughout NFCF in contrast to NPP, where the bulk of nuclear material is located in the reactor core or fuel storage areas. For example, nuclear materials in current reprocessing plants are present for most or part of the process in solutions that are transferred between vessels used for different parts of the processes, whereas in most NPPs nuclear material is present in concentrated form as solid fuel.

Second, NFCFs are often characterized by more frequent changes in operations, equipment and processes, which are necessitated by treatment or production campaigns, new product development, research and development, and continuous improvement.

Third, the treatment processes in most NFCFs use large quantities of hazardous chemicals, which can be toxic, corrosive and/or combustible.

Fourth, the major steps in NFCFs consist of chemical processing of fissile materials, which may result in the inadvertent release of hazardous chemicals and/or radioactive substances, if not properly managed.

Fifth, the range of hazards in some NFCFs can include inadvertent criticality events, and these events can occur in different locations and in association with different operations.

Finally, in NFCFs a significantly greater reliance is placed on the operator, not only to run a facility during its normal operation, but also to respond to anticipated operational occurrences and accident conditions [9].

Whereas the reactor core of an NPP presents a very large inventory of radioactive material and coolant at high temperature and pressure and within a relatively small volume, the current generation of NFCFs operate at near ambient pressure and temperature and with comparatively low inventories at each stage of the overall process. Accidents in NFCFs may have relatively low consequences when compared against nuclear power plants. Exceptions to this are facilities used for the large scale interim storage of liquid fission products separated from spent fuel and, where applicable, facilities for separating and storing plutonium.

In some cases in an NFCF, there are rather longer timescales involved in the development of accidents and less stringent process shutdown requirements are necessary to maintain the facility in a safe state, as compared to an NPP. Nevertheless, the INPRO area of NFCF safety applies the principles of the DID concept and encourages the NFCF designers to enhance the independence of DID levels in new facilities. NFCFs also often differ from NPPs with respect to the enhanced importance of ventilation systems in maintaining their safety even under normal operation. This is because nuclear materials in these facilities are in direct contact with ventilation or off-gas systems. Various forms and types of barriers between radioactive inventories and operators may have different vulnerabilities. Fire protection and mitigation assume greater importance in an NFCF due to the presence of larger volumes of organic solutions and combustible gases. With fuel reprocessing or fuel fabrication facilities, the wide variety of processes and material states such as liquids, solutions, mixtures and powders needs to be considered in safety analysis.

From this point of view, the safety features of NFCFs are often more similar to chemical process plants than those of NPPs. In addition, radioactivity and toxic chemical releases and criticality issues warrant more attention in NFCFs than in NPPs . Further comparisons of the relevant features of an NPP, a chemical process plant and an NFCF are presented in Table 2.

| Feature | NPP | Chemical Process Plant | NFCF |

|---|---|---|---|

| Type of hazardous materials | Mainly nuclear and radioactive materials | A variety of materials dependent on the plant (acids, toxins, explosives, combustibles, etc.) | - Nuclear and radioactive materials; - Acids, toxins, combustibles (nitric acid, hydrogen fluoride, solvents, process and radiolytic hydrogen, etc.) |

| Areas of hazardous sources and inventories | - Localized in core, fuel storage and spent fuel pool; - Standardized containment system, cooling of residual heat, criticality management |

Distributed in the process and present throughout the process equipment | - Present throughout the process equipment in the facility; - Consisting both of nuclear materials and chemically hazardous materials; |

| Physical forms of hazardous materials (at normal operation) | - Fuel in general is in solid form ; - Other radioactive materials in solid, liquid, gaseous form |

Wide variety of physical forms dependent on the process, e.g. solid, liquid, gas, slurry, powder | - Wide variety of physical forms of nuclear and radioactive materials; - Wide variety of physical forms of chemically hazardous materials |

As outlined above, from a safety point of view, NFCFs are characterized by a variety of physical and chemical treatments applied to a wide range of radioactive materials in the form of liquids, gases and solids. Accordingly, it is necessary to incorporate a correspondingly wide range of specific safety measures in these activities. Radiation protection requirements for the personnel are more demanding, especially in view of the many human interventions required for the operation and maintenance of an NFCF. The safety issues encountered in various NFCFs have been discussed in [8][9]. A comprehensive description of the safety issues of fuel cycle facilities is provided in Ref[11].

For most existing NFCFs, the emphasis is on the control of operations using administrative and operator controls to ensure safety as well as engineered safety features, as opposed to the emphasis on engineered safety features used in reactors. There is also more emphasis on criticality prevention in view of the greater mobility (distribution and transfer) of fissile materials. Because of the intimate human contact with nuclear materials in the process, which may include (open) handling and transfer of nuclear materials in routine processing, special attention is warranted to ensure worker safety. Potential intakes of radioactive materials require control to prevent and minimize contamination and thus ensure adherence to specified operational dose limits. In addition, releases of radioactive materials into the facilities and through monitored and unmonitored pathways can result in significant exposures.

The number of physical barriers in an NFCF that are necessary to protect the workers, the environment and the public depends on the potential internal and external hazards, and the consequences of failures; therefore the barriers are different in number and strength for different kinds of NFCFs (the graded approach). For example, in mining, the focus is on preventing contamination of ground or surface water with releases from uranium mining tails. Toxic chemicals and uranium by-products are the potential hazards of the conversion stage and for forms of in-situ mining. In enrichment and fuel fabrication facilities (with no recycling of separated or recovered nuclear material from spent fuel), safety is focused on preventing criticality in addition to avoiding contamination via low-level radioactive material.

It might be possible to enhance safety features in a nuclear energy system by co-location of front end (e.g. mining/ milling, conversion and enrichment, and fuel production facilities) and back end (reprocessing and waste management) facilities. This would have benefits through minimal transport, optimisation and alignment of processes, avoiding multiple handling of radioactive materials in different plants of the fuel cycle and comprehensive and integrated waste treatment and storage facilities.

Compared to safety of operating NPPs, only limited open literature is available on the experience related to safety in the operation of NFCFs. Examples of United States Nuclear Regulatory Commission regulation are provided in Refs[12][13][14][15][16]. Safety of and regulations for NFCFs have been discussed in IAEA meetings and conferences [8][9]. Aspects of uranium mining have been reported extensively [17][18][19][20][21][22][23][24]. The Nuclear Energy Agency of the Organization for Economic Cooperation and Development published a comprehensive report on safety of nuclear installations in 2005[25]. Safety guides on conversion/enrichment facilities, fuel fabrication, reprocessing and spent fuel storage facilities have also been published by the IAEA[26][27][28][29][30].

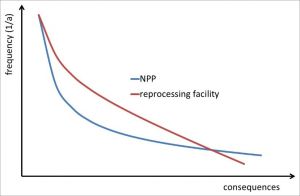

It is obvious that in well-designed NFCFa, the safety related events that have a high hazard potential will have low frequency of occurrence and vice versa. For example, Fig. 1 (modified from Ref[31]) conceptually compares the relationship between potential consequences and frequency for safety related events in a nuclear power plant and a reprocessing facility.

The figure demonstrates that, compared to accidents in an NPP, an NFCF may have relatively higher consequences of accidents having higher probability of occurrence, e.g. accidental criticality. However, accidents with very high consequences have essentially lower probability than in NPPs and can only occur in a few high inventory NFCFs, typically large reprocessing plants and associated liquid high level waste interim storage facilities[32].

Application of the Defence-In-Depth concept to NFCFs

The original concept of defence in depth was developed by the International Safety Advisory Group (INSAG) and published in 1996 [33]. Historically it is based on the idea of multiple levels of protection, including consecutive barriers preventing the release of radioisotopes to the environment, as already formulated in Ref[34]:

“All safety activities, whether organizational, behavioural or equipment related, are subject to layers of overlapping provisions, so that if a failure were to occur it would be compensated for or corrected without causing harm to individuals or the public at large”

The application of DID to NFCFs takes into account their following features:

- The energy potentially released in a criticality accident in a fuel cycle facility tends to be relatively small. However, generalization is difficult as there are several fuel fabrication or reprocessing options for the same or different type of fuels;

- The power density in a fuel cycle facility in normal operation is typically several orders of magnitude less than in a reactor core;

- In a reprocessing facility, irradiated fuel pins are usually mechanically cut (chopped) into small lengths suitable for dissolution and the resultant solution is further subjected to chemical processes. This may create a possibility for larger releases of radioactivity to the environment on a routine basis as compared to reactors;

- The likelihood of a release of chemical energy is higher in fuel cycle facilities of reprocessing, re-fabrication, etc. Chemical reactions are part of the processes used for fresh fuel fabrication as well as for reprocessing of spent nuclear fuel.

The numbers of barriers to radioactive releases to the environment depend in different types of NFCFs on the forms, conditions, inventories and radiotoxicity levels of the processed nuclear materials. Table 3 gives a summary of the typical numbers of barriers to radioactive releases to the environment in existing NFCFs at different steps of nuclear fuel cycle.

| Facility type | Number of barriers | |

|---|---|---|

| Mining | 0–1 | |

| Milling / Processing / Conversion | 1–2 | |

| Enrichment | 2 | |

| Fuel manufacture | Low radioactivity | 1–2 |

| High radiotoxicity | 2–3 | |

| Fresh fuel storage | 2 | |

| Fresh fuel transportation | 2 | |

| Spent fuel transportation | 3 | |

| Spent fuel storage | Wet | 2 |

| Dry | 3 | |

| Reprocessing | 3 | |

| Reprocessing product storage including waste | Low radiotoxicity | 2 |

| High radiotoxicity | 3 | |

Table 4 summarises how INPRO uses the DID concept within this sustainability assessment methodology for the area of NFCF safety. The INPRO methodology applies this DID concept to all NCFCs as part of a graded approach that considers the level of risks in each individual facility.

| Level | DID level purpose[11] | INPRO methodology proposals for NFCFs |

|---|---|---|

| 1 | Prevent deviations from normal operation and the failure of items important to safety. | Enhance prevention by increasing the robustness of the design, and by further reducing human error probabilities in the routine operation of the plant. Enhance the independence among DID levels. |

| 2 | Detect and control deviations from operational states in order to prevent anticipated operational occurrences at the facility from escalating to accident conditions. | Give priority to advanced monitoring, alarm and control systems with enhanced reliability and intelligence. Together with qualified procedures for operators, the systems need to be able to anticipate and detect abnormal operational states, prevent their progression and restore normalcy. Enhance the independence among DID levels. |

| 3 | Prevent releases of radioactive material and associated hazardous material or radiation levels that require off-site protective actions. | Decrease the expected frequency of accidents. Achieve fundamental safety functions by an optimized combination of inherent safety characteristics, passive safety features, automatic systems and operator actions; limit and mitigate accident consequences; minimize reliance on human intervention, e.g. by increasing grace periods. Enhance the independence among DID levels. |

| 4 | Mitigate the consequences of accidents that result from failure of the third level of DID and ensure that the confinement function is maintained, thus ensuring that radioactive releases are kept as low as reasonably achievable. | Decrease the expected frequency of severe plant conditions; increase the reliability and capability of systems to control and monitor severe accident sequences; reduce the characteristics of the source term of the potential emergency off-site releases of radioactivity Avoid ‘cliff-edge’ failures of items important to safety. Enhance the independence among DID levels. |

| (5) | Mitigate the radiological consequences and associated chemical consequences of releases or radiation levels that could potentially result from accidents. | Emergency preparedness is covered in another area of the INPRO methodology called Infrastructure[35]. |

Necessary INPUT for a sustainability assessment in the area of safety of nuclear fuel cycle facilities

Definition of a nuclear energy system to be assessed

See NES for clear definition of nuclear energy system.

For a NES sustainability assessment in this area of the INPRO methodology, the NFCF to be assessed and a reference design have to be defined. Where possible, the reference design has to be determined as an NFCF of most recent design operating in 2013, preferably from the same designer as the assessed facility, and complying with the current safety standards. In such a case, the INPRO assessment in this area is expected to demonstrate an increased safety level to achieve long term sustainability in the assessed NFCF in comparison to the reference design. If a reference design cannot be identified within the same technology lineage, a similar existing comparable technology or, when other options are not available, an existing facility of different technology used for the same purpose can be used as a reference. If a reference design cannot be defined, it needs to be demonstrated through the assessment of RD&D results that the NFCF design employs the best international practice to achieve a safety level comparable to most recent technology and that the assessed facility is therefore state of the art.

INPRO assessment by a technology user

An INPRO assessor, being a technology user, needs sufficiently detailed design information on the NFCF to be assessed. This includes information relating to the design basis of the plant, engineered safety features, confinement systems, human system interfaces, control and protection systems, etc. The design information needs to highlight the structures, systems and components (important to safety) that are of evolutionary or innovative design[36] and this could be the focus of the INPRO assessment.

In addition to the information on the NFCF to be assessed, the INPRO assessor needs the same type of information on a reference plant design in order to perform a comparison of both designs. Details of the information needed are outlined in the discussion of the INPRO methodology criteria in the following sections.

If not available in the public domain, the necessary design information could be provided by the designer (potential supplier). Therefore, a close co-operation between the INPRO assessor as a technology user and the designer (potential supplier) is necessary as detailed in the INPRO methodology overview manual.

In addition, all relevant operational and maintenance data and history of the reference facility will be useful as well as any records of modifications, any failures and incidents in the reference NFCF or similar facilities.

Results of safety assessments

To assess sustainability, the INPRO assessor will need access to the results of a safety assessment of a reference plant and to the basic design information of the NFCF to be assessed that includes a safety analysis that evaluates and assesses challenges to safety under various operational states, AOO and accident conditions using deterministic and probabilistic methods; this safety assessment is supposed to be performed and documented by the designer (potential supplier) of the NFCF to be assessed.

For an NFCF to be assessed using the INPRO methodology, the safety assessment would need to include details of the RD&D carried out for advanced aspects of the design. Such information is usually found in a (preliminary) safety report (or comparable document) that may be available in public domain or could be provided by the designer (potential supplier) of the NFCF. Thus, as stated before, a close co-operation between the INPRO assessor as a technology user and the designer (potential supplier) is necessary.

INPRO assessment by a technology developer

In principle, an INPRO assessment can be carried out by a technology developer at any stage of the development of an advanced NFCF design. This assessment can be performed as an internal evaluation and does not require results of the formal safety assessment. However, it needs to be recognized that the extent and level of detail of design and safety assessment information available will increase as the design of an advanced NFCF progresses from the conceptual stage to the development of the detailed design. This will need to be taken into account in drawing conclusions on whether an INPRO methodology sustainability requirement for safety has been met by the advanced design.

One potential mode for the technology developer’s use of the INPRO methodology is in performing a limited scope assessment. Limited scope INPRO assessments can be focused on specific areas and specific nuclear energy system installations having different levels of maturity. A limited scope study may assess the facility design under development and may help highlight gaps to be closed in on-going RD&D studies and define the scope of data potentially needed to make future judgements on system sustainability.

Other sources of INPUT

The assessor can use the IAEA Fuel Incident Notification and Analysis System (FINAS) and other international and national event reporting systems for specific and general information relevant to the technology type and detailed design of an advanced NFCF.

INPRO basic principle for sustainability assessment in the area of safety of nuclear fuel cycle Facilities

This section presents some background on the INPRO basic principle (BP) and user requirements (UR) for sustainability assessment in the area of NCFC safety. It is noted that the INPRO methodology in this area was originally developed with a nuclear power plant in mind and had to be adapted, especially at the criterion level, to the individual NFCF.

INPRO basic principle for sustainability assessment in the area of NFCF safety: The planned NFCF is safer than the reference NFCF. In the event of an accident, off-site releases of radionuclides and/or toxic chemicals are prevented or mitigated so that there will be no need for public evacuation.

The main goal of the INPRO basic principle is to encourage the designer/developer to increase the safety level of a new facility to be installed after 2013. To achieve this goal, the INPRO methodology proposes that NFCF designers/ developers undertake the following key measures:

- Incorporate enhanced defence in depth into an advanced NFCF design as a part of the fundamental safety approach.

- Incorporate, when appropriate, inherently safe characteristics and passive systems into advanced NFCF designs as a part of a fundamental safety approach to excel in safety and reliability.

- Reduce the risk from radiation exposures to workers, the public and the environment during construction/ commissioning, operation, and decommissioning of an advanced NFCF.

- Perform sufficient RD&D work to bring the knowledge of NFCF characteristics and the capability of analytical methods used for design and safety assessment of a plant with innovative features to at least the same confidence level as for a reference plant.

- Take human factors into account in the design and operation of an NFCF and establish and maintain a safety culture in all organizations involved in a nuclear power program.

The INPRO methodology has developed seven user requirements to specify in more detail the main measures presented above. These user requirements are to be fulfilled primarily by the designer (developer, supplier) of the NES but also in some cases by the operator. As stated before, the role of the INPRO assessor is to check, based on evidence provided by the designer and operator, whether they have implemented the necessary measures as required by the INPRO methodology. The following sections provide rationale and background information for each user requirement (UR).

UR1

|

ᅠ User requirement UR1: robustness of design during normal operationᅠ

|

|---|

|

INPRO user requirement UR1 for sustainability assessment in the area of NFCF safety: The assessed NFCF is more robust than the reference design with regard to operation and systems, structures and components failures.

The first INPRO user requirement, UR1, for sustainability assessment in the area of NFCF safety is mostly related to the first level of DID, which is focused on preventing AOOs, i.e. deviations from normal operation and failures of items important to safety. AOOs are defined as those conditions of operation that are caused by events associated with internal or external hazards expected to occur one or more times during the lifetime of an NFCF but that do not cause any significant damage to items important to safety nor lead to accident conditions requiring safety features (Level 3 of DID) to control. |

UR2

|

ᅠ User requirement UR2: detection and interception of AOOsᅠ

|

|---|

|

INPRO user requirement UR2 for sustainability assessment in the area of NFCF safety: The assessed NFCF has improved capabilities to detect and intercept deviations from normal operational states in order to prevent AOOs from escalating to accident conditions. |

UR3

|

ᅠ User requirement UR3: design basis accidentsᅠ

|

|---|

|

INPRO user requirement UR3 for sustainability assessment in the area of NFCF safety: The frequency of occurrence of DBAs in the assessed NFCF is reduced. If an accident occurs, engineered safety features and/or operator actions are able to restore the assessed NFCF to a controlled state, and subsequently to a safe state, and the consequences are mitigated to ensure the confinement of radioactive and/or toxic chemical material. Reliance on human intervention is minimal, and only required after sufficient grace period. |

UR4

|

ᅠ User requirement UR4: severe plant conditionsᅠ

|

|---|

|

INPRO user requirement UR4 for sustainability assessment in the area of NFCF safety: The frequency of an accidental release of radioactivity into the environment is reduced. The source term of accidental release into the environment remains well within the envelope of the reference facility source term and is so low that calculated consequences would not require public evacuation. |

UR5

|

ᅠ User requirement UR5: independence of DID levels AND inherent safety characteristicsᅠ

|

|---|

|

INPRO user requirement UR5 for sustainability assessment in the area of NFCF safety: An assessment is performed to demonstrate that the DID levels are more independent from each other than in the reference design. To excel in safety and reliability, the assessed NFCF strives for better elimination or minimization of hazards relative to the reference design by incorporating into its design an increased emphasis on inherently safe characteristics. |

UR6

|

ᅠUser Requirement UR6: human factors related to safetyᅠ

|

|---|

|

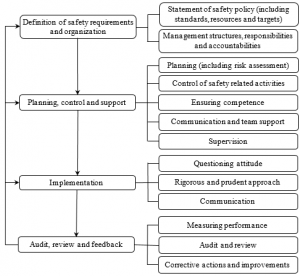

INPRO user requirement UR6 for sustainability assessment in the area of NFCF safety: Safe operation of the assessed NFCF is supported by accounting for HF requirements in the design and operation of the facility, and by establishing and maintaining a strong safety culture in all organizations involved in the life cycle of the facility.  FIG. 2. Components of safety management[44]. The INPRO task group on safety has summarized the possible negative contributions to accident hazards from human actions into three groups:

As a common design principle, it needs to be ensured that:

It is expected that the ability to predict human response to both normal and abnormal situations will improve significantly over the next decades and will have a major impact on facility design and operation. Simulator technologies are constantly improving and can thus allow more realistic representations (and progression predictions) of transient and accident plant states in expert systems.

The term ‘safety culture’ was introduced in 1986 by the International Safety Advisory Group in a summary report of the post-accident review meeting on the Chernobyl accident[46] and was further elaborated in Refs[34][47]. Ref[47] defined safety culture in the following way :

This definition emphasizes that safety culture relates to the structure and style of organizations (governmental institutions, owner/operator, and industrial entities) as well as to the habits and attitudes of individuals (managers and employees). Safety culture demands a commitment to safety on three levels: policy, management and individual[44][48][49][50][51][52][53][54]. The policy level requires a clear statement of safety policy, adequate management structures and related resources, and the establishment of self-regulation (by regular review). To fulfil their commitments, managers need to define clearly the responsibilities, accountabilities and safety practices for the control of work, ensure that staff are qualified and trained, establish a system of rewards and sanctions, and perform audits, reviews and benchmarking comparisons. In carrying out their tasks, individuals need to maintain an attentive and questioning attitude, adopt a rigorous and prudent approach, and participate in effective communications (see Fig. 2 taken from Ref[44]). The importance of the management system for safety culture in nuclear facilities has been described in Ref[44], which defines this system as “those arrangements made by the organization for the management of safety in order to promote a strong safety culture and achieve good safety performance”. Organizations go through a number of stages in developing their safety cultures[48]:

Ref[49] presents practical advice on how to strengthen safety culture. The status of requirements for establishing, implementing, assessing and continually improving a management system for safety culture are reflected in the IAEA Safety Standards, e.g. Refs[50][51][52][53]. These include generic guidance on establishing, implementing, assessing and continually improving such a management system.

As outlined above, safety culture is a complex concept (see also Ref[54]) and there is no single indicator that can be used for determining its status. To capture both observable behaviour and people’s attitudes and basic beliefs, several methods need to be applied including interviews, focus groups, questionnaires, observations and document reviews. |

UR7

|

ᅠUser requirement UR7: necessary RD&D for ADVANCED designsᅠ

|

|---|

|

INPRO user requirement UR7 for sustainability assessment in the area of NFCF safety: The development of innovative design features of the assessed NFCF includes associated research, development and demonstration (RD&D) to bring the knowledge of facility characteristics and the capability of analytical methods used for design and safety assessment to at least the same confidence level as for operating facilities. A sound knowledge of the phenomena (e.g. chemical reaction rates, partition coefficients, solubility), and component and system behaviour, where applicable, is required to support the development of analysis tools for NFCF accidents. Hence, the more a facility differs from operating designs, the more RD&D is required. RD&D provides the basis for understanding events that threaten the integrity of barriers defined by the defence in depth concept. RD&D is also expected to provide information to reduce allowances for uncertainties in design, operating envelopes, and in estimates of accident frequencies and consequences.

Figure 3 gives an overview of tasks to be performed in defining the necessary RD&D for an innovative design. |

Concluding remarks

To assess long term sustainability with regard to the safety of an NFCF to be installed after 2013, the INPRO methodology has formulated one basic principle with seven user requirements. INPRO’s sustainability assessment approach in the area of NFCF safety is based on the IAEA Safety Standards and, as derived from those, the application of a DID oriented strategy for comparing the safety attributes of the assessed NFCF designs to those of reference designs. The assessment approach is supported by an increased emphasis on inherent safety characteristics and, where appropriate, passive safety features. Greater independence of the different levels of defence in depth is considered a key element for avoiding failure propagation from one DID level to the next. Using a graded approach, the number of physical barriers in a nuclear facility that are necessary to protect the environment and people depends on the potential internal and external hazards and the potential consequences of failures; therefore, the barriers will vary in number and strength depending on the type of NFCF.

The end point of the enhanced defence in depth strategy of the INPRO methodology is that, even in case of accidents, no emergency environmental releases of radioactivity and/or toxic chemicals can occur that would necessitate public evacuation. Nevertheless, effective emergency planning, preparedness and response capabilities will remain a prudent requirement.

Adaptation of the INPRO methodology to uranium and thorium mining and milling

See Mining and milling of uranium and thorium to find necessary background with a short description of the main processes found in a facility for uranium and thorium mining and milling (or processing). The sustainability assessment method is described in terms of the corresponding criteria of the INPRO methodology in the area of safety, which are adapted as necessary to the specific issues potentially affecting this type of NFCF.

The INPRO methodology for sustainability assessment in the areas of nuclear safety was developed originally with a focus on nuclear power plants and was later adapted to NFCFs. The use of the INPRO methodology for an assessment of a uranium or thorium mining and milling facility required significant modifications of the methodology, as several user requirements and criteria are not directly applicable for such a facility. This section presents how the INPRO methodology in the area of NFCF safety was adapted to a mining and milling facility.

INPRO basic principle for sustainability assessment of uranium and thorium mining and milling facilities in the area of safety

INPRO basic principle for sustainability assessment of uranium or thorium mining and milling facility in the area of safety: The planned uranium or thorium mining and milling facility is safer than the reference mining and milling facility.

The rationale for the BP was provided in Section 4. The definition of the reference NFCF is at NFCF page. This definition comprises several options that can be used to determine the reference NFCF depending on the type of facility assessed and the specific technology used. In the context of uranium and thorium mining and milling, the concept of a reference design is primarily applicable to a milling facility and tailings management facility. Definition of the reference facility for the mine assessed can be fairly challenging compared to other types of NFCF because of very broad variety of technologies used in mining as stipulated by the different types of deposits and different geological/ hydrological conditions. However, when a reference facility cannot be defined for a given mine, at least the systems dealing with radiological hazards (e.g. shielding, ventilation, protection against radon and dust) can be assessed against INPRO criteria.

The INPRO methodology has defined a set of requirements for mining and milling facilities and criteria for the assessment. Several INPRO criteria defined for the sustainability assessment of mining and milling facilities in the area of safety involve consideration of ‘state of the art’ concept as the acceptance limits. These sustainability assessment criteria are related to those specific features of the mining and milling facilities that are important to radiation protection and safety (control of radiation sources). The criteria should therefore not be interpreted as nuclear safety recommendations, industrial safety requirements or general requirements for the mining or milling technology used.

The INPRO methodology user requirements pertaining to mining and milling facilities are displayed in Table 5.

| User requirement | Criteria | Indicator (IN) and Acceptance Limit (AL) |

|---|---|---|

UR1: Robustness of design during normal operation:

The design for the mining/ milling facility assessed is more robust than the reference design with regard to operation and systems, structures and component failures. |

CR1.1: Design of normal operation systems | IN1.1: Robustness of design of normal operation systems. |

| AL1.1: Superior to that in the reference design. | ||

| CR1.2: Facility performance | IN1.2: Facility performance attributes. | |

| AL1.2: Superior to those in the reference design | ||

| CR1.3: Inspection, testing and maintenance | IN1.3: Capability to inspect, test and maintain. | |

| AL1.3: Superior to that in the reference design. | ||

| CR1.4: Failures and deviations from normal operation | IN1.4: Expected frequency of failures and deviations from normal operation. | |

| AL1.4: Lower than that in the reference design. | ||

| CR1.5: Occupational dose | IN1.5: Occupational dose values during normal operation and AOOs. | |

| AL1.5: Lower than the dose constraints. | ||

UR2: Detection and interception of AOO:

The mining/milling facility assessed is capable to monitor, detect and intercept deviations from normal operational states in order to prevent AOOs from escalating to accident conditions. |

CR2.1: I&C systems and operator procedures | IN2.1: I&C system to monitor, detect, trigger alarms, and, together with operator actions, intercept and compensate AOOs that could lead to radiation exposure of workers. |

| AL2.1: Availability of such systems and/or operator procedures. | ||

| CR2.2: Grace periods for AOOs | IN2.2: Grace periods until human (operator) actions are required after detection (and alarm) of AOOs. | |

| AL2.2: Adequate grace periods are defined in the design analyses. | ||

UR3: Accidents:

The frequency of occurrence of accidents in the mining/ milling facility assessed is reduced. If an accident occurs, engineered safety features and/or operator actions are able to restore the facility assessed to a controlled state, and subsequently to a safe state, and the consequences are mitigated to ensure the confinement of nuclear and/or toxic chemical material. Reliance on human intervention is minimal, and only required after sufficient grace period. |

CR3.1: Frequency of accidents | IN3.1: Calculated frequency of occurrence of accidents. |

| AL3.1: Lower than that in the reference design. | ||

| CR3.2: Engineered safety features and operator procedures | IN3.2: Reliability and capability of engineered safety features and/or operator procedures. | |

| AL3.2: Superior to those in the reference design. | ||

| CR3.3: Grace periods for accidents | IN3.3: Grace periods for accidents until human intervention is necessary. | |

| AL3.3: Longer than those in the reference design. | ||

| CR3.4: Barriers | IN3.4: Number of confinement barriers maintained (intact) after an accident. | |

| AL3.4: At least one. | ||

UR4: Severe plant conditions

|

None | User requirement UR4 was found to be not directly applicable to a mining and milling facility |

UR5: Inherent safety characteristics:

To excel in safety and reliability, the mining/ milling facility assessed strives for elimination or minimization of some hazards relative to the reference design by incorporating into its design an increased emphasis on inherently safe characteristics. |

CR5.1: Minimization of hazards | IN5.1: Examples of hazards: fire, flooding, release of radioactive material, radiation exposure, etc. |

| AL5.1: Hazards minimized according to the state of the art. | ||

UR6: Human factors related to safety:

Safe operation of the mining/ milling facility assessed is supported by accounting for HF requirements in the design and operation of the facility, and by establishing and maintaining a strong safety culture in all organizations involved in the life cycle of the facility. |

CR6.1: Human factors | IN6.1: Human factors addressed systematically over the life cycle of the mining/ milling facility assessed. |

| AL6.1: Evidence is available. | ||

| CR6.2: Attitude to safety | IN6.2: Prevailing safety culture. | |

| AL6.2: Evidence is provided by periodic safety reviews. | ||

UR7: RD&D for advanced designs:

The development of innovative design features of the mining/ milling facility assessed includes associated RD&D to bring the knowledge of facility characteristics and the capability of analytical methods used for design and safety assessment to at least the same confidence level as for operating facilities. |

CR7.1: RD&D | IN7.1: RD&D status. |

| AL7.1: RD&D defined, performed and database developed. | ||

| CR7.2: Safety assessment | IN7.2: Adequate safety assessment. | |

| AL7.2: Approved by a responsible regulatory authority. |

User requirement UR1: Robustness of design during normal operation

The rationale for UR1 was described in Section 4.1. User requirement UR1 is focused on preventing AOOs. For a mining and milling facility, examples of AOOs that could potentially cause radiation doses to workers include the following:

- In an underground mine, a malfunction of the ventilation system (needs to be compensated by switchover to a backup system);

- In a milling facility, a malfunction of the dust prevention equipment in the crushing and grinding unit (leading to accumulation of radioactive dust);

- In a milling facility, a (small) leakage of (liquid or gaseous) radioactive material in the processing unit.

It is acknowledged that an insufficient radiation protection program (RPP) or a failure by the workers to follow its (administrative) procedures (e.g. keeping distance and limiting presence, wearing of protective respiratory equipment or dose monitoring devices) and to apply (technical) measures defined in the RPP (e.g. shielding) could be also a reason for radiation exposure of workers in a mining and milling facility. This issue of human behaviour (safety culture) is covered in user requirement UR6.

INPRO methodology selected five criteria for UR1 as displayed in Table 5.

Criterion CR1.1: Design of normal operation systems

|

ᅠIndicator IN1.1: Robustness of design of normal operation systems.ᅠ

|

|---|

|

Acceptance limit AL1.1: Superior to that in the reference design. |

Criterion CR1.2: Facility performance

|

ᅠIndicator IN1.2: Facility performance attributes.ᅠ

|

|---|

|

Acceptance limit AL1.2: Superior to those of the reference design. |

Criterion CR1.3: Inspection, testing and maintenance

|

ᅠIndicator IN1.3: Capability to inspect, test and maintain.ᅠ

|

|---|

|

Acceptance limit AL1.3: Superior to that in the reference design. |

Criterion CR1.4: Failures and deviations from normal operation

|

ᅠIndicator IN1.4: Expected frequency of failures and deviations from normal operation.ᅠ

|

|---|

|

Acceptance limit AL1.4: Lower than that in the reference design. |

Criterion CR1.5: Occupational dose

|

ᅠIndicator IN1.5: Occupational dose values during normal operation and AOOs.ᅠ

|

|---|

|

Acceptance limit AL1.5: Lower than the dose constraints.

Ref[38] further recommends using dose constraints “for optimization of protection and safety, the intended outcome of which is that all exposures are controlled to levels that are as low as reasonably achievable, economic, societal and environmental factors being taken into account”. The role of dose constraints is explained in Refs[19][57]. In the INPRO methodology, the dose constraints concept is discussed in more detail in the manual on environmental impact of stressors[37]. |

User requirement UR2: Detection and interception of AOO

The rationale of UR2 was provided in Section 4.2. The criteria selected for user requirement UR2 are presented in Table 5.

Criterion CR2.1: I&C systems and operator procedures

|

ᅠIndicator IN2.1: I&C system to monitor, detect, trigger alarms and, together with operator actions, intercept and compensate AOOs that could lead to radiation exposure of workers.ᅠ

|

|---|

|

Acceptance limit AL2.1: Availability of such systems and/or operator procedures. |

Criterion CR2.2: Grace periods for AOOs

|

ᅠIndicator IN2.2: Grace periods until human (operator) actions are required after detection (and alarm) of AOOs.ᅠ

|

|---|

|

Acceptance limit AL2.2: Adequate grace periods are defined in the design analyses. |

User requirement UR3: Accidents

The rationale of UR3 was provided in Section 4.3. UR3 for mining and milling facilities deals with accidents . Examples of accidents for mining and milling facilities include:

- In an underground mine, a complete failure of the ventilation system;

- In a milling facility, a rupture of components (pipes, vessels) in the chemical processing unit of the milling facility with subsequent (large) spillage of radioactive and/or chemically toxic material;

- A fire in an underground mining facility;

- A loss of the integrity of the tailings (storage and disposal) facility due to external hazards such as flooding (or dam break) with a significant release of solid and/or liquid radioactive and chemically toxic material to the environment .

Other external hazards (defined in Sections 2.1 and 2.6 of NFCF), such as earthquakes, flooding, etc, can also lead to accidents in all types of mines and milling facilities. As stated before, the facilities need to be designed against both external and internal hazards.

The criteria selected for user requirement UR3 are presented in Table 5.

Criterion CR3.1: Frequency of accidents

|

ᅠIndicator IN3.1: Calculated frequency of occurrence of accidents.ᅠ

|

|---|

|

Acceptance limit AL3.1: Lower than that in the reference design. |

Criterion CR3.2: Engineered safety features and operator procedures

|

ᅠIndicator IN3.2: Reliability and capability of engineered safety features and/or operator procedures.ᅠ

|

|---|

|

Acceptance limit AL3.2: Superior to those in the reference design. |

Criterion CR3.3: Grace periods for accidents

|

ᅠIndicator IN3.3: Grace periods for accidents until human intervention is necessary.ᅠ

|

|---|

|

Acceptance limit AL3.3: Longer than those in the reference design. |

Criterion CR3.4: Barriers

|

ᅠIndicator IN3.4: Number of confinement barriers maintained (intact) after an accident.ᅠ

|

|---|

|

Acceptance limit AL3.4: At least one. |

User requirement UR4: Severe plant conditions

User requirement UR4 was found to be not directly applicable to a mining and milling facility.

User requirement UR5: Inherent safety characteristics

Rationale of UR5 was provided in Section 4.5. The criterion selected for user requirement UR5 is presented in Table 5.

Criterion CR5.1: Minimization of hazards

|

ᅠIndicator IN5.1: Examples of hazards: fire, flooding, release of radioactive material, radiation exposure, etc.ᅠ

|

|---|

|

Acceptance limit AL5.1: Hazards minimized according to the state of the art. |

Descriptions of the user requirement UR6 and corresponding criteria are common for all NFCFs discussed in this report (i.e. mining/ milling, conversion, enrichment, fuel fabrication, spent fuel storage and reprocessing). The rationale of UR6 was provided in Section 4.6. There are two aspects of safety covered in this user requirement. The first one is focused on the design of equipment related to safety to minimize human errors, and the second one covers the attitude to safety of people in nuclear facilities and related organizations. The criteria selected for user requirement UR6 ar presented in Table 5.

Criterion CR6.1: Human factors

|

ᅠIndicator IN6.1: Human factors addressed systematically over the life cycle of the mining/ milling facility assessed.ᅠ

|

|---|

|

Acceptance limit AL6.1: Evidence is available.

Addressing human factors in the design of safety related equipment and the radiation protection program (RPP) in mining and milling facilities and other NFCFs will increase the level of safety. Human errors during the facility operation, including maintenance, inspections and tests, and decommissioning need to be considered in the facility safety analysis. |

Criterion CR6.2: Attitude to safety

|

ᅠIndicator IN6.2: Prevailing safety culture.ᅠ

|

|---|

|

Acceptance limit AL6.2: Evidence is provided by periodic safety reviews. |

User requirement UR7: RD&D for advanced designs

A description of the user requirement UR7 and corresponding criteria are common for all NFCFs discussed in this report (i.e. mining/ milling, conversion, enrichment, fuel fabrication, spent fuel storage and reprocessing). The rationale of UR7 was provided in Section 4.7. The user requirement UR7 discusses the necessary RD&D effort for developing a facility with primarily innovative but also evolutionary design features.

The criteria selected for user requirement UR7 are presented in Table 5.

Criterion CR7.1: RD&D

|

ᅠIndicator IN7.1: RD&D status.ᅠ

|

|---|

|

Acceptance limit AL7.1: RD&D defined, performed and database developed.

The acceptance limit AL7.1 of CR7.1 is met if evidence available to the INPRO assessor shows that for an NFCF with innovative (or evolutionary) design features relevant to safety sufficient RD&D has been performed prior to start-up of the facility. |

Criterion CR7.2: Safety assessment

|

ᅠIndicator IN7.2: Adequate safety assessment.ᅠ

|

|---|

|